Ohio State University Induction Machine

Overview

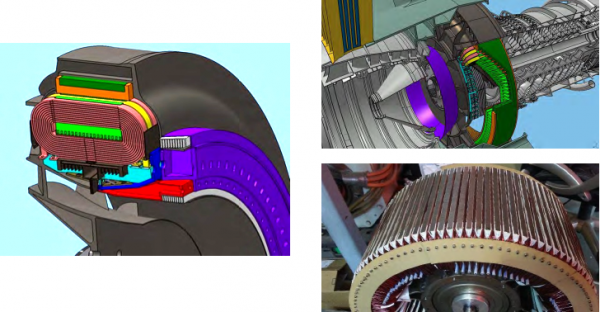

Topology

- 2.7 MW ring induction motor with a performance goal of 13 kW/kg and efficiency of >96 percent

- Relatively high pole count and fundamental frequency.

- The Variable Cross-Section Wet Coil (VCSWC) technology utilizes direct fluid cooling on a tape conductor, which is the width of the slot in the active area, and widens at the end turns to maximize heat transfer and therefore current density.

Aircraft Level Integration

- 10MW motor integrated with a turbofan.

Validation

- Motor 1 (300kW) shown validated cooling path and stator manufacturing.

- Motor 2 (1MW) validates tape coil fabrication and stator integration.

- Motor 3 (2.7MW) validates performance.