Icing Research

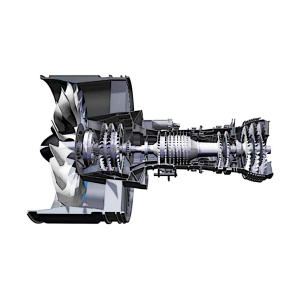

NASA’s icing research involves the development of tools and methods for evaluating and simulating the growth of ice on current and future aircraft surfaces or inside the engines and the effects that ice may have on the behavior of aircraft in flight.