Electric Machines

Electric Machines

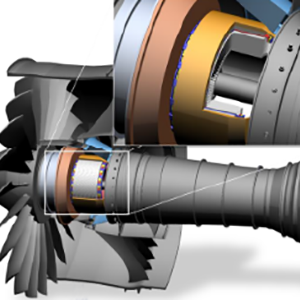

All electrified aircraft require motors and/or generators, also known as electric machines. Research in the electrical power area focuses on building lightweight, high-efficiency motors and power converters in the megawatt class. Megawatt-level components were selected because they support the implementation of partially turboelectric and hybrid electric propulsion up to the single-aisle aircraft class, and fully turboelectric or hybrid electric systems for smaller aircraft. While specific power several times higher than industrial motors has been recognized as a key need for several years, the system benefits of combining high specific power with high efficiency have more recently become clear.

NASA is sponsoring work to achieve power densities 2-3 times the state of the art for machines in the MW or larger class, with ongoing efforts to develop megawatt-class motors at the University of Illinois (1MW) and at The Ohio State University (up to 10 MW). The three major machine types that are currently being developed include permanent magnet, induction, and wound field. Additionally, a 1.4-MW motor is being designed at NASA Glenn Research Center. The key performance and design parameters for each of these efforts are shown in Table 2.

| Continuous power rating, MW |

Specific power goal, kW/kg |

Efficiency goal, % |

Motor type |

Speed | Nominal dimensions |

|

| University of Illinois | 1 | 13 | >96 | Permanent magnet | 18,000 | Cylinder 0.45 m by 0.12 m |

| Ohio State University | 2.7 | 13 | >96 | Induction | 2,500 | Ring 1.0 m by 0.12 m |

| NASA Glenn Research Center | 1.4 | 16 | >98 | Wound field | 6,800 | Cylinder 0.40 m by 0.12 m |