Planetary Exploration Test Facilities

There are several state-of-the-art test rigs and facilities at the NASA Glenn Research Center (GRC) operated by GRC’s mTRAX Planetary Exploration team. These rigs serve to test planetary roving vehicle systems and components in simulated planetary and lunar conditions.

Facility Overview

There are several state-of-the-art test rigs and facilities at the NASA Glenn Research Center (GRC) operated by GRC’s mTRAX Planetary Exploration team. Most of the facilities are located in the Engine Research Building (ERB). These rigs serve to test planetary roving vehicle systems and components in simulated planetary and lunar conditions. Most of the test capabilities are focused on the interactions between rover components (such as tires and excavation tools) and the terrain, though there are environmental test capabilities as well. A few examples of ongoing research in these labs includes conducting full-scale vehicle mobility tests to determine new methods for traversing challenging terrain, evaluating the performance of novel rover tires in lunar and Martian environments, and testing various excavation techniques for digging on the Moon.

Capabilities

The following test rigs and facilities all fall under the mTRAX Planetary Exploration umbrella:

Simulated Lunar OPErations (SLOPE) Lab

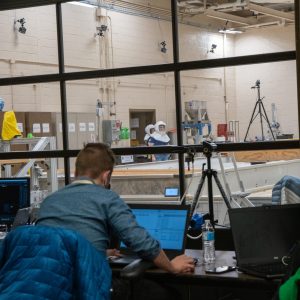

The Simulated Lunar OPErations (or SLOPE) Lab serves to provide controlled test conditions to evaluate the tractive performance of roving vehicles on simulated Lunar and Martian terrain. Because the lab is indoors, the facility has stable temperature and humidity levels which limits variability in soil conditions between tests. Full-scale vehicles, or sub-systems and components, can be tested here.

The lab consists of three distinct test areas:

- 12m x 3m x 0.3m soil tank filled with GRC-1 lunar simulant. Here, vehicles can traverse prepared lunar simulant as well as obstacles to assess performance. A drawbar pull rig can be positioned at the end of the test bed, which applies a desired resistive force to the rover via a smart-winch system. The tractive performance of the rover or it’s mobility components can be assessed as a function of drawbar pull force.

- 6m x 5m x 0.3m adjustable tilting soil tank. Using a hydraulic lift system, the tilt-bed is adjustable up to 45 degrees of inclination for sloped surface operations; however the maximum angle is typically limited by the angle of repose of the simulants in the bed. Currently the tilt-bed is filled with GRC-1 but can be changed out to the desired granular material.

- 12m x 3m x 0.6m “Sink Tank”. This soil tank is twice as deep as the others and filled with a high-sinkage material called “Fillite”. Due to its particle shape, this material mimics the wind-blown dune soil on Mars and has extremely low shear strength, which produces a very challenging trafficability case for roving vehicles.

The SLOPE lab is equipped with 32 infrared OptiTrak motion tracking cameras; 20 are mounted permanently on the walls and 12 are on tripods, providing a full 360-degree field of view. The test vehicles or subjects can be outfitted with trackers so that the rover position and orientation, with sub millimeter accuracy, can be captured in real time.

As mentioned above, the soil tanks in the SLOPE Lab are currently filled with two simulants: GRC-1 lunar simulant, and Fillite high-sinkage medium. GRC-1 is a custom poorly-graded soil consisting of semi-angular silica particles. It was developed to match the bulk strength properties of the equatorial lunar terrain explored during the Apollo missions, with a focus on targeting the “softer”, more conservative range of properties with respect to vehicle mobility. The soil density can be controlled providing a range of conditions. Fillite consists of hollow alumino-silicate microspheres and is intended to mimic the wind-blown dune soil found on Mars that has produced entrapped conditions for rovers. Though the material is not a high-fidelity simulant, it has low bearing and shear strength, and produces a very challenging case for roving vehicles. The material in the soil tanks can be changed out for alternate simulants upon request.

View a virtual tour of the SLOPE Lab.

TRaction and Excavation Capabilities (TREC) Rig

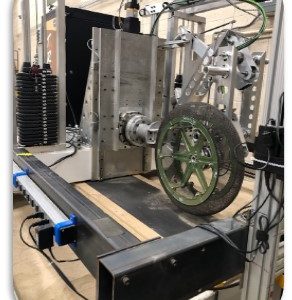

The TRaction and Excavation Capabilities (TREC) Rig is a single wheel dynamometer used to determine the tractive performance of various wheel and tire designs in simulated lunar and Mars soils. The TREC Rig offers independent motion control of the carriage and the tire such that forced slip conditions ranging from 0 to 90% can be achieved. The tire load is adjustable from approximately 90 N to 1300 N, including off-loading capability. The linear speed is also adjustable with a maximum rate of 6 cm/s. Tires up to 95 cm in diameter can be tested in the rig’s current configuration; however, it can be adapted for larger tires if needed.

An in-hub mounted 6-axis load cell captures the drive force and the ground force such that a net traction versus slip curve can be generated. In addition, a laser displacement sensor is used to measure and record the tire sinkage with time.

The TREC rig features two available simulants contained in adjacent soils tanks that are 2m x 1m x 0.75m in depth. One tank contains GRC-3, a custom silty-sand lunar soil simulant consisting of semi-angular silica particles and Bonnie silt to provide added strength for ISRU considerations such as excavation. It can be prepared to a wide range of densities. The other tank contains a commercial sand identified as #90: a poorly graded silica sand designed to represent the aeolian regions of the Martian terrain.

A semi-automated rake and screed method is used to prepare the simulants to repeatable conditions. Similar to SLOPE, the simulant in the TREC soil tanks can be removed and replaced with alternate granular media upon request.

In addition to single wheel tractive performance, the dynamic and static net traction of a tire or wheel over bedrock can be obtained using the TREC rig.

Excavation Lab

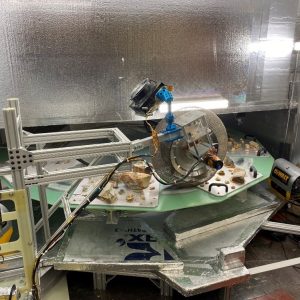

This laboratory is used to test and develop excavation tools and techniques for lunar and planetary human and robotic surface operations in granular simulated regolith.

The Advanced Planetary Excavator (APEX), a heavy-duty robotic arm capable of excavating from multiple adjacent soil bins, is used to evaluate excavation tools and forces. The APEX is a 4 degree-of-freedom, backhoe-like, robotic arm designed to expose only sealed rotary joints to environmental dust. It can rotate 360 degrees around a vertical axis and has a >2m reach, fine position control, and power and ethernet available to the implement on the end of the arm. Excavation tools can be lowered to desired digging depths and driven at controlled rates on pre-programmed paths while digging forces are measured using a 6-axis load cell. The APEX operates by electrical linear actuators.

Currently, GRC-3B, a specific silica sand and silt mixture with particle size distribution that is similar to lunar regolith, is used to simulate the geotechnical properties of lunar regolith. Other simulants can be used. A dust enclosure with HEPA filter air exchange surrounds the APEX and soil bins to protect operators from respiratory hazards. The soil bin sits on a shaker table used to compact the simulant.

Test Capabilities

- Test duration: User defined

- Power to experiments: Excavation tools can be tethered (wall AC power) or powered from APEX (nominally 300 VDC)

- Data: force, torque, mass of soil dug, depth, velocity, data from tool, power

- Thermal environment of test hardware: Lab ambient (air conditioned)

- Operation: Joy-stick control and designed planned trajectories for repeatability

Advanced Planetary Excavator (APEX) Specifications

- APEX can rotate 360 degrees.

- 3-meter maximum swing around radius with bucket and load cell.

- APEX has electrically powered linear actuators.

| Joint | Max Speed | Full Throw |

| Shoulder | 4.67 cm/s | 5.42 sec |

| Elbow | 9.37 cm/s | 2.71 sec |

| Wrist | 11.71 cm/s | 1.31 sec |

- Max vertical force = 1165 lbf / 5184 N

- As installed in Excavation Lab:

- Max vertical force controlled to 900 lbf / 4005 N

- Max horizontal force controlled to 400 lbf / 1780 N

- 6 axis load cell:

- Range: 1300 N Fx, Fy and 3900 N Fz; 203 N-m Tx, Ty, Tz

- FS uncertainty: 1.25% Fx, Fy, Tx, Ty; 2.00 % Fz and Tz

- Diameter: 156.5 mm

Other Specifications

- Facility 208 VAC – 3 phase power is converted to 325 VDC, 100 amps to power the actuators.

- Pea Gravel bin: 61cm W x 91cm L x 51cm H

- GRC-3B soil bin: 76.2cm W x 183cm L x 76cm H – sits on shaker table

- Dump bin sits on 61cm x 61cm platform scale to weigh delivered load.

- Shaker table: 81cm W x 188cm L x 36cm H, 22.24 kN Max. load.

- Digital power meter is used with 50-amp shunt to measure DC power to APEX.

- Platform scale

- 61 x 61 cm

- Range = 2224 N x 0.22 N

Extreme Cyclic Environmental Load (XCEL) Test Rig

The Extreme Cyclic Environmental Load (XCEL) Test Rig is a hydraulic load frame coupled with an environmental chamber sized to enclose a full-scale wheel or tire. This test rig is used for cyclic radial compression tests at temperatures ranging from 77K to 370K. Liquid Nitrogen or liquid carbon dioxide can be used to cool the chamber to the desired temperature. The nominal inner dimensions of the environmental chamber are 139 cm tall x 101 cm deep x 121 cm wide; the maximum tire size is dependent on the hardware and fixture needs, as well as stroke length. The nominal cyclic rate is 1-5 Hz depending on the desired stroke length.

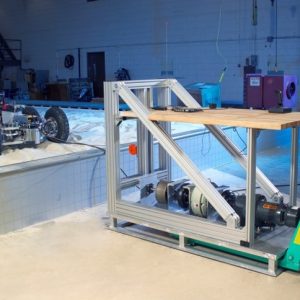

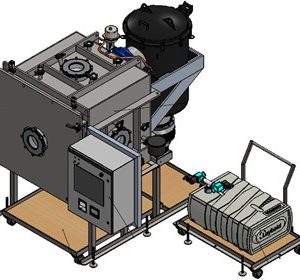

Extreme Terrain Endurance Rig (XTERra)

The Extreme Terrain Endurance Rig (XTERra) is a new single wheel life test rig used to evaluate the durability of new wheels and tires at planetary temperatures over representative terrain elements. The XTERra carousel and tire are independently driven to create a forced slip condition ranging from 0 to 100%. The maximum linear speed is on the order of 10 to 13 cm/s depending on the desired tire load. The rig is designed to operate at temperatures ranging from 77K and 323K. Currently tires up to 70 cm in diameter can be tested in

XTERra; however accommodations can be made for larger tires.

During a life test, the load and temperature are recorded with time. Up to eight different video frames can also be recorded during a test.

Terrain panels are custom designed and can be created with a range of obstacle and terrain types.

Note: The rig will become online in December of 2022 for room temperature testing and in the spring of 2023 for cryogenic testing.

Vacuum Operations in Dust Environment (VOiD) Facility

The test rig provides capability to study sub-meter cubed experiments in simulated extraterrestrial environments. Designed to operate under thermal and vacuum control with regolith simulant in the chamber, the chamber serves to promote the Technology Readiness Level (TRL) of payloads past component-level testing.

Technical Capabilities

A thermal shroud inside the chamber is cooled with LN2 dewars and heated with internal heaters. A series of filters and a throttle valve allow safe pump down with simulant in the chamber.

| Name | Value | Unit |

| Internal Working Dimensions | 35 W X 35 D X 32.5 H (89 X 89 X 82.5) | in (cm) |

| Working Temperature | -180 to +150 (-290 to +300) | °C (°F) |

| Vacuum Level | 10-6 | Torr |

The test rig includes 4 mounting points on the ceiling for instrumentation, each with a 50 lb load capacity.

The table below outlines several auxiliary ports for use by the customer for thermocouple, power, and data feedthrough. All of the auxiliary ports are KF / QF or LF type flanges, which allow for faster and cheaper instrument installation. The DN-250 ports and 2 of the DN-40 ports are line-of-sight to the center of the chamber.

| Size | Type | Quantity |

| DN-40 | KF / QF | 14 |

| DN-63 | LF | 2 |

| DN-250 | LF | 5 |

Note: this rig is currently being built and is slated to be operational in Summer of 2023

Contact

Engine Research Building (ERB)

Facility Manager: Gwynn Severt

216-433-8310

Gwynn.A.Severt@nasa.gov

Test Facility Management Branch

Branch Chief: Michael S. McVetta

216-433-2832

michael.s.mcvetta@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.