BXF

Boiling Experiment Facility (BXF)

The Boiling Experiment Facility (BXF) is designed to operate in the Microgravity Science Glovebox (MSG) on the International Space Station (ISS). The BXF consists of a boiling chamber mounted within a containment vessel. The boiling chamber has three science heaters, pressure and temperature measurement instrumentation, a bellows assembly for pressure control, and pumps for liquid conditioning. The containment vessel provides the second and third levels of containment for the test fluid should it leak from the boiling chamber. Standard rate (29.97 Hz) video cameras are mounted inside the chamber to provide two orthogonal side-view images and a standard side-view image. The high-speed video camera is mounted on the exterior of the containment vessel wall and acquires 4 seconds of images through the bottom of the heater at 500 images per second.

Overview

The Boiling Experiment Facility (BXF) will accommodate two separate investigations, BXF–MABE (Microheater Array Boiling Experiment) and BXF–NPBX (Nucleate Pool Boiling Experiment), to examine fundamental boiling phenomena. BXF is planned for the Microgravity Science Glovebox (MSG) located in the U.S. Laboratory on the International Space Station (ISS). The purpose of the BXF is to validate models being developed for heat transfer coefficients, critical heat flux, and the pool boiling curves.

Background

Boiling efficiently removes large amounts of heat by generating vapor from liquid. It is used to produce steam to turn turbines in electrical power plants, cool high-powered electronic devices such as supercomputers, purify chemical mixtures, and even cook dinner. An upper limit, called the critical heat flux, exists where the heater generates so much vapor that the liquid can not reach the heated surface. Continued heating above this limit for prolonged periods can cause the heater to burn itself out. Determination of the critical heat flux in microgravity is essential for designing cooling systems for space.

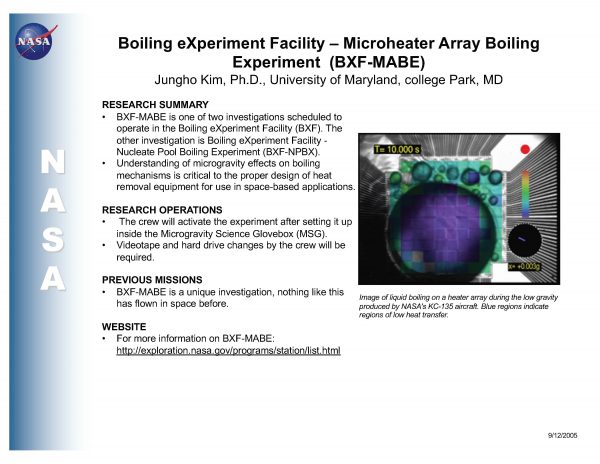

Pool boiling generates vapor bubbles by heating a stagnant body of liquid. It is a complex phase change process here the hydrodynamics, heat transfer, mass transfer, and interfacial phenomena are tightly interwoven. By conducting tests in microgravity, it is possible to assess the effect of buoyancy on the overall boiling process and assess the relative magnitude of other effects and phenomena such as surface tension forces, liquid momentum forces, and microlayer evaporation.

Relevance

Boiling is relevant to space-based hardware and processes such as heat exchangers, cryogenic fuel storage, and electronic cooling due to the large amounts of heat that can be removed with small increases in the temperature of the heat transfer fluid. This reduces the temperature difference between the heat source and radiator. For space applications, this reduction in the temperature difference equates to a higher radiator temperature which can reduce the radiator area and weight.

Pool boiling is an effective means for studying flow boiling. Some models that are used to predict flow boiling heat transfer coefficients consist of both pool boiling and liquid-phase forced flow convection terms. The liquid-phase term is well-quantified in all gravity environments. Pool boiling is also the limiting case of flow boiling whereby the flow becomes zero.

Science Objectives

The BXF uses normal-perfluorohexane as the test fluid and will operate between pressures of 60 to 244 kPa and temperatures of 35 to 60 °C. Pressure and bulk fluid temperature measurements will be made, and standard rate video will be acquired.

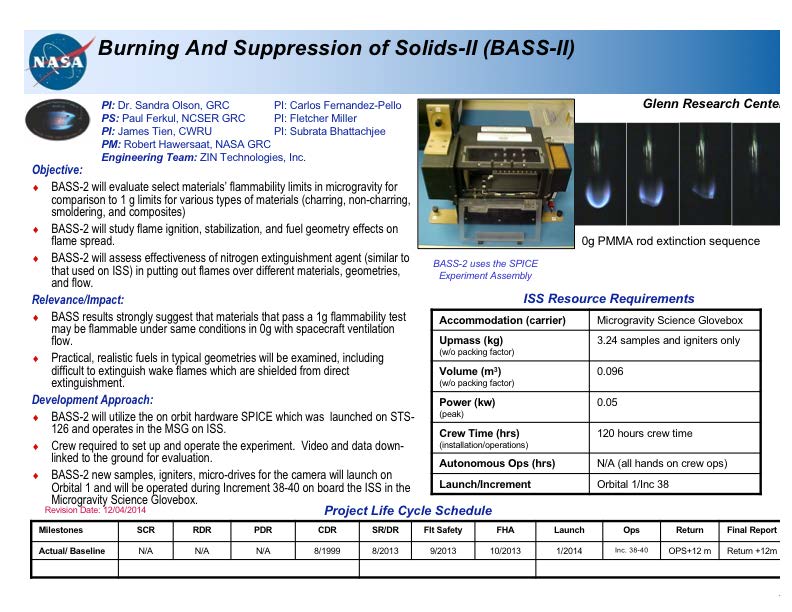

The objective of MABE is to determine the local boiling heat transfer mechanisms in microgravity for nucleate and transition boiling and the critical heat flux by examining the position of the liquid and vapor adjacent to the heater. MABE uses two 96-element microheater arrays, 2.7 by 2.7 mm and 7.0 by 7.0 mm in size, to measure localized heat fluxes while operating at a constant temperature. Most boiling experiments in the past have operated at constant wall heat flux with a much larger heater, allowing only time and space-averaged measurements to be made. Each heater is on the order of the bubble departure size in normal gravity, but significantly smaller than the bubble departure size in reduced gravity. A high speed video system will be used to visualize the boiling process through the bottom of the MABE heater arrays.

The other experiment, NPBX uses a 85-mm-diameter heater wafer that has been “seeded” with five individually controlled nucleation sites to study bubble nucleation, growth, coalescence and departure. The experiment will selectively activate these nucleation sites in order to understand bubble growth, detachment, and subsequent motion of single and large merged bubbles under reduced-gravity conditions.

Hardware Description

The BXF is currently scheduled to fly on Utilization Flight-5 to the ISS with facility integration into the MSG and operation during Increment 26.

The hardware consists of a boiling chamber mounted within a containment vessel. The boiling chamber has three science heaters (one for NPBX and two heater arrays for MABE), pressure and temperature measurement instrumentation, a bellows assembly for pressure control, and pumps for liquid conditioning. The containment vessel provides the second and third levels of containment for the test fluid in the event of a leak from the boiling chamber of the test fluid. Standard rate video cameras are mounted inside the chamber to provide two orthogonal side-view images of the vapor bubble during tests with the NPBX heater and a single side view of the vapor bubble during MABE testing. The high-speed video camera is mounted on the exterior of the containment vessel wall and acquires 4 seconds of images through the bottom of the MABE heater at 500 images per second.

An avionics box contains the data acquisition and control unit, removable hard drives, indicator panel, and the control unit for the high-speed video camera. The avionics box interfaces with the MSG mobile launch computer, the high-speed video camera, and the BXF-embedded controller boards within the containment vessel.

Related Documents

Currently updating…

Publications

Currently updating…

Contact Information

Microheater Array Boiling Experiment (MABE)

Principal Investigator:

-

- Prof. Jungho Kim, University of Maryland

Nucleate Pool Boiling eXperiment (NPBX)

Principal Investigator:

-

- Prof. Vijay Dhir, University of California-LA

Project Scientists:

-

- John McQuillen, NASA GRC;

- David Chao, NASA GRC

Project Manager:

-

- William Sheredy, NASA GRC

Engineering Team:

-

- ZIN Technologies, Inc.