Sensor Arrays

Leak Sensor Array

In leak monitoring of launch vehicles, it is important to detect low concentrations of hydrogen and other fuels to avoid explosive conditions that could harm personnel and damage the vehicle. Dependable vehicle operation also relies on the timely and accurate measurement of these leaks. Measuring the levels of hydrogen and hydrocarbons (fuel) and oxygen can give an appraisal of whether there is an explosive condition in a given region.

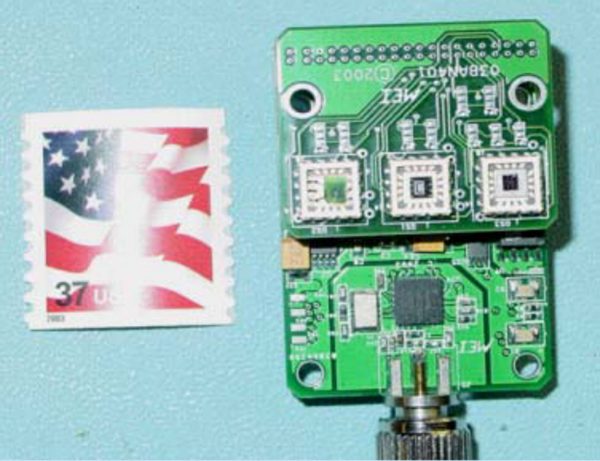

A MEMS-based leak detection sensor system that integrates hydrogen, oxygen, and hydrocarbon sensors into a single package has been achieved. The work creates an smart, adaptable system that has the surface area of a postage stamp which can simultaneously measure both fuel and oxygen, transmit data through telemetry, and has low power consumption.

This smart sensor package contains the required analog and digital electronics, including processing, memory, and communications devices to enable a stand-alone system. This basic hardware approach for hydrogen has been matured for potential implementation on the next generation launch vehicles. The approach is to produce a complete leak detection system that can be placed in a number of locations. This core smart sensor hardware can also be applied to a range of other applications.

Fire and Environmental Monitoring

Fire detection is extremely important onboard space and commercial aircraft to avoid catastrophic situations and to verify the operational status of the vehicle. False alarm rates from traditional fire detectors previously were caused by changes in humidity, condensation on the detectors surface, or contamination from the contents of the vehicle.

The work produced a microsensor array to measure the chemical signature of a fire to provide more reliable fire detection. The CO and CO2 sensors are central to this array and other sensors are included to improve the accuracy of the measured chemical signature providing indications of conditions which can produce false alarms in other detectors.

Some of the same sensors are also of interest for environmental monitoring of a cabin environment. For example, CO and CO2 are also core measurements to assure a safe cabin environment, but at different concentrations than needed for fire detection. Modifications to the core CO and CO2 sensor technology provide other sensors for this measurement range. The result is a multiparameter sensor array that can be used for both environmental monitoring as well as fire detection.

This fire and environmental monitoring work has produced prototype systems that are both hand-held and stationary. Recent work has involved a prototype wearable monitor for first responders to, e.g., wildfire conditions.

Engine Emissions Sensor Array

A high-temperature engine emissions gas sensor array, in effect a high-temperature electronic nose, has been developed to detect a variety of gases of interest for emissions and chemical process monitoring such as hydrocarbons, nitrogen oxides, carbon monoxide, carbon dioxide, and oxygen. Several of these arrays could be placed around the exit of the engine exhaust to monitor the emissions produced by the engine.

The signals produced by this emissions sensor array could be analyzed to determine the constituents of the emission stream, and this information can then be used to control those emissions. This emissions sensor array concept uses materials that are suitable for high-temperature environments and that are composed of different types of microsensor platforms (diodes, resistors, and electrochemical cells) to give a wider range of inputs.

This approach has been demonstrated multiple times at the exhaust of a jet engine and a method to use the data to correlate with the health state of the engine and has been suggested from the data.