How the PSL Worked

A brief overview of how the PSL No. 1 and 2 was able to test large engines in simulated altitude conditions.

Overview

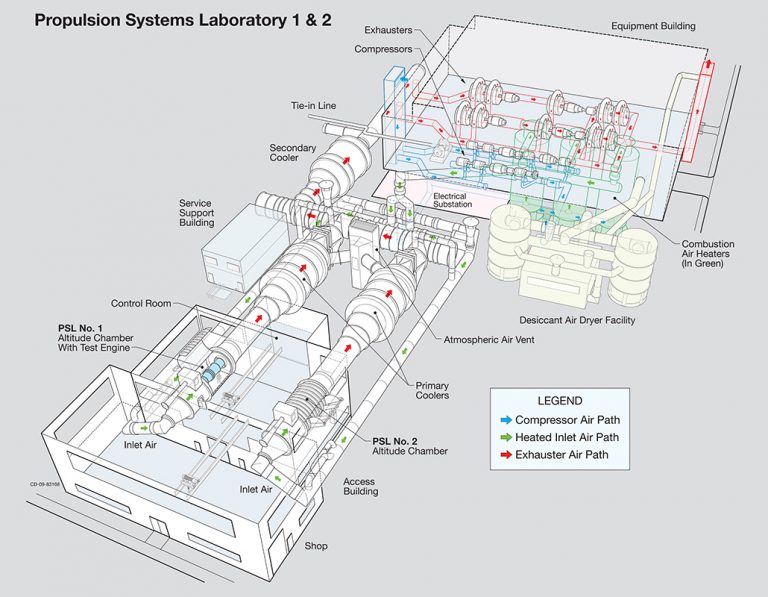

The Propulsion Systems Laboratory (PSL) at NASA Glenn Research Center originally contained two altitude chambers for testing full-scale turbojet, ramjet, and rocket engines in conditions that replicated those encountered during flight. A large hatch allowed the installation of the engine onto a moveable thrust stand within the test section. Compressors in the Equipment Building pumped air at high speeds towards one of the test chambers. The air was conditioned as it passed through the refrigeration equipment, heaters, and dryer to produce the temperatures found at high altitudes or supersonic speeds. Large exhausters, also located in the Equipment Building, reduced the air pressure within the test chamber to create the thin air of high altitudes.

As the air flow entered the chamber, it passed through straightening vanes and was ducted directly to the engine inlet in the test section. Operators in a control room located between the two chambers ran the tests. Cameras and instrumentation collected data from inside the chamber. After exiting the test section, the engine’s hot exhaust gases passed through a primary cooler that reduced the gases’ temperature. Some of the remaining heat was dissipated through the atmospheric air vent, and the remainder was cooled as it was drawn through the secondary cooler. The air was then pumped into the Equipment Building and vented into the atmosphere.

Glossary

Altitude: Considered the elevation above an acknowledged level. In aerospace situations, this level is usually mean sea level. Height is the elevation above a point on the ground.

Propulsion System: The entire system in which an engine operates. This includes inlets, nozzles, fuel supply, and other components besides the engine. Engine components often behave differently when integrated into the entire propulsion system than they do when isolated.

Altitude Simulation: The creation of conditions in a test facility that are similar to those encountered at high altitudes. The temperature, pressure, moisture content, speed, and other factors must be replicated.

Test Section: Portion of a test facility where the engine or test article and sensors are placed. The entire test facility is focused on creating the proper conditions in this test section.

Exhauster: A pump that removes gas or air from one location and expels it in another. By removing air from a test chamber, one can create the low pressures found at higher altitudes.

Compressor: A turbine-powered machine that compresses gas or air. By compressing the air, it is forced from the storage in the compressor through a pipe or line.

Cooler: A device that removes heat from the surrounding air. There are different methods of accomplishing this. One of the most frequently used methods uses tubes filled with water or Freon (DuPont). As the hot air passes around the tubes, the heat is transferred to the water. The water is pumped away and the air temperature is reduced.