Electromagnetic Interference Laboratory

The Electromagnetic Interference Laboratory (EMI) offers analysis of hardware requirements and specification comparisons, electronic component testing, testing of hardware for shielding effectiveness, and final qualification testing of experiments.

Facility Overview

The Electromagnetic Interference (EMI) Laboratory offers several Electromagnetic Compatibility (EMC) services like EMC hardware design to meet the desired requirement, specification comparisons, consultation during design development, and prefabrication analyses. The EMI Lab provides intermediate testing as the design progresses, testing for shielding effectiveness, filtering, and grounding, final qualification testing of experiments in flight configuration, and testing at customer locations for items too large to fit in the EMI Laboratory shielded room.

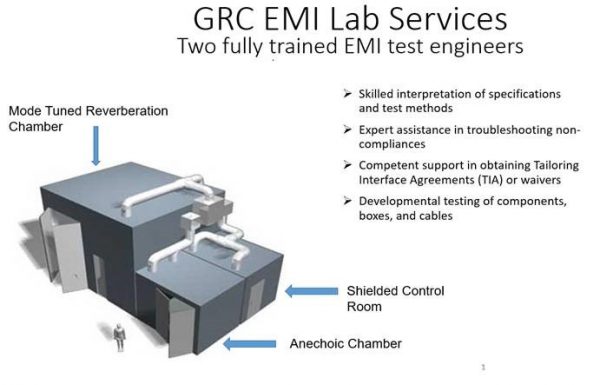

This facility consists of three shielded rooms, two test chambers, and a control room. All walls, ceiling, and floors are constructed of 26-gauge galvanized steel sheets laminated to both sides of a structure core.

The rooms meet the electromagnetic wave attenuation requirements used by the National Security Agency (NSA). They prevent transmission of electromagnetic waves into, or out of, the enclosure, which provides low electric and magnetic field ambient conditions. Electrical power is provided through filtered AC lines to eliminate transfer of interfering signals such as radio, TV, and RADAR.

The large shielded enclosure is a fully functional package with support for stirred and tuned mode operation with Statistical Mode Averaged Reverberation test. This methodology of test is good for Immunity test or Shielding Effectiveness test.

Quick Facts

The EMI Lab has successfully verified every piece of flight hardware to leave Glenn Research Center (GRC) since its completion in circa 1995. Significant cost and schedule savings have been realized by projects with the ability to test EMI compliance on-site.

Recent upgrades to the facility include anechoic chamber treatment for small payloads, mode-tune reverberation chamber characterization for large payloads and high frequency test equipment will allow GRC to be a key NASA program participant, testing its Spaceflight hardware to increasingly stringent program requirements.

The EMI Lab also aligns GRC with the administration’s renewed focus on alternative energy sources, since all electric systems (automobile, solar power, wind, battery) will require adherence to Federal Communications Commission and possibly Conducted Emissions regulations for Electromagnetic Interference.

| Name | Electromagnetic Interference Laboratory |

|---|---|

| Shielded Test Facilities | 32′ x 24′ x 16′ (Large)12′ x 16′ x 8′ (Small) |

- The EMI facility consists of three shielded rooms, two test chambers, and a control room. The rooms meet the electromagnetic wave attenuation requirements used by the National Security Agency (NSA).

- Wi-fi is available outside shield rooms for connectivity with NASA wi-fi devices.

Capabilities

Model Support Systems

- Large test enclosure: 32 by 24 by 16 ft, Door: 10 by 14 ft

- Small test enclosure: 12 by 16 by 8 ft, Door: 6 by 7 ft

- Test Control Room: 10 by 12 by 8 ft

| Test Specification | Emissions Tests | Method |

|---|---|---|

| SSP30237/SSP30238 | CE01 | Automated |

| CE03 | Automated | |

| CE07 | Manual | |

| RE02 | Automated | |

| AC Magnetic | Automated/Manual | |

| DC Magnetic | Manual | |

| MIL-STD-461F,G | CE101 | Automated |

| CE102 | Automated | |

| RE101 | Automated/Manual | |

| RE102 | Automated |

| Test Specification | Susceptibility Tests | Method |

|---|---|---|

| SSP30237/SSP30238 | CS01 | Automated |

| CS02 | Automated | |

| CS06 | Manual | |

| RS02 | Manual | |

| RS03PL | Automated | |

| MIL-STD-461F,G | CS101 | Automated |

| CS114 | Automated | |

| CS115 | Manual | |

| CS116 | Manual | |

| RS103 | Automated |

Contact

Electromagnetic Interference Laboratory (EMI)

Facility Manager: John E. Thomas

216-433-2658

John.E.Thomas@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.