Aero-Acoustic Propulsion Laboratory

The Aero-Acoustic Propulsion Laboratory (AAPL) is a world-class facility for conducting aero-propulsion noise reduction research.

Facility Overview

With over 20 years of testing experience in acoustic research and development, the AAPL, located at NASA’s Glenn Research Center, is a world-class facility providing outstanding testing services in aircraft propulsion acoustic noise reduction and performance research.

Unique in testing capabilities and size, the AAPL dome is 65 ft high by 130 ft in diameter, providing an anechoic testing environment for engine component research and development. To provide a reflection free acoustic environment, 17,000 custom-designed 2‑ft thick fiberglass wedges are mounted on the dome’s interior walls and floor areas adjacent to the test rigs. The acoustically treated dome walls are designed specifically to attenuate sound. Together, these elements provide an acoustic testing environment that exceeds the acoustic research testing objectives set forth by NASA and industry.

AAPL houses three state-of-the-art acoustic test rigs, the Nozzle Acoustic Test Rig (NATR), Small Hot Jet Acoustic Rig (SHJAR), and the DGEN Aero-Propulsion Research Turbofan (DART).

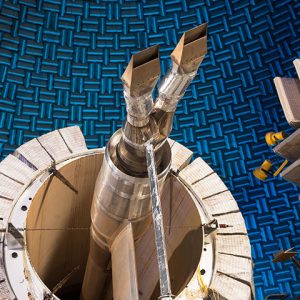

Nozzle Acoustic Test Rig (NATR)

Designed specifically for acoustic and aerodynamic testing of advanced nozzle concepts, the NATR Free Jet, a 53-in. diameter, free-jet acoustic wind tunnel, is used to test a variety of aircraft technologies at simulated take-off and landing flight conditions up to Mach 0.35. The High-Flow Jet Exit Rig (HFJER) is used to mount test nozzle hardware within the NATR Free Jet. The HFJER is supplied with heated air to simulate the core and bypass flows of a turbofan engine. The NATR Free Jet and HFJER are uniquely suited to investigate engine nozzle acoustic performance, installation effects, and other aero-propulsion research as desired.

Located 50 ft from a test model, a fixed microphone array is used to acquire sideline and fly-by acoustic data. The data is processed and analyzed in real time during testing, improving data quality while reducing time and costs. The AAPL is one of the largest acoustic facilities in the world to feature a far-field measurement arena used for propulsion simulations.

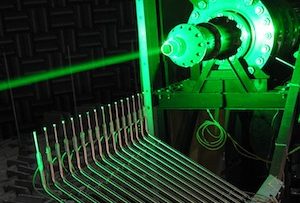

Small Hot Jet Acoustic Rig

The SHJAR provides researchers with an all-in-one platform to economically evaluate thrust performance, acoustic performance, and plume turbulence characteristics of new nozzle concepts.

The SHJAR can conduct laser-based plume turbulence studies with particle imaging velocimetry (PIV), shadowgraphy, Schlieren imaging, and a traversing plume-survey that can acquire high-resolution temperature and pressure profiles.

A 10-ft custom-built far-field measurement arena is used to obtain sideline or fly-by acoustic data. The data collected is processed and analyzed in real time during testing, optimizing test utilization and data quality while reducing time and costs.

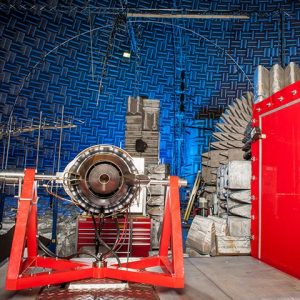

DGEN Aero-Propulsion Research Turbofan

The DART provides a test bed for a variety of multi-discipline research.The DGEN 380 engine is a small turbofan that is representative of larger, more modern turbofan engines. The engine produces 570 lb of thrust and is approximately 48 in. long by 16 in. in diameter.

DART test bed can be used for:

- Fan noise research (liners, fan)

- Engine control development (embedded controls, fault tolerance)

- Installation effects (embedded designs, distributed sources)

- Instrumentation development (sensors, telemetry)

- Measurement technologies (arrays, source separation)

Quick Facts

The Aero-Acoustic Propulsion Laboratory (AAPL) is a world-class facility providing outstanding testing services in aircraft noise reduction, with an emphasis in engine nozzle and fan components. Unique in testing capabilities and size, the AAPL dome is 65-ft high by 130-ft in diameter and covered with acoustic treatment internally to provide an anechoic testing environment for engine component research and development.

| Nozzle Acoustic Test Rig (NATR) Free Jet Wind Tunnel | ||

|---|---|---|

| Test section speed, Mach | 0.0 to 0.35 | |

| Simulated altitude, ft | Sea level | |

| Test section total temperature, ˚R | Ambient | |

| NATR High-Flow Jet Exit Rig (HFJER) | ||

| Flow configurations | Single (core) | Dual (core + bypass) |

| Maximum nozzle pressure ratio | 4.5 | 4.5 |

| Maximum core temperature, ˚F | 1,425 | 1,280 |

| Maximum fan/bypass temperature, ˚F | – | 300 |

| Maximum air flow rate (450 psig), lbm/s | 30 | 30 |

| Fuel | Compressed natural gas | Compressed natural gas |

| *Optional independent third-stream airflow available. | ||

| Small Hot Jet Acoustic Rig (SHJAR) | ||

| Flow configurations | Single (core) | |

| Maximum nozzle pressure ratio | 8 | |

| Maximum temperature, ˚F | 1,300 | |

| Maximum air flow rate (450 psig) lbm/s | 6 | |

| Fuel | Gaseous hydrogen | |

| DGEN Aero-Propulsion Research Turbofan (DART) | ||

| Fan diameter, in. | 14 | |

| Bypass ratio | 7.6 (two-spool unmixed flow) | |

| Gear ratio | 3.32 | |

| Thrust, lbf | 570 | |

| Engine control | Manual or automatic control via Full-Authority Digital Engine Control (FADEC) | |

- The AAPL provides an anechoic testing environment for acoustic measurements of aero-propulsion components.

- The SHJAR can be used to test single stream nozzles up to 3 inches in diameter, with nozzle pressure ratios up to 8, exhaust velocities up to Mach 2.0, and exhaust temperatures of up to 1,300°F.

- The NATR is a free-jet acoustic wind tunnel which became operational in March 1989.

- The NATR uses a large far-field arena is used to acquire fly-by and sideline acoustic data of nozzle concepts at simulated flight conditions up to Mach 0.35.

Capabilities

The Aero-Acoustic Propulsion Lab houses three state-of-the-art test rigs for conducting aero-propulsion related research:NATR,SHJARandDART.

Nozzle Acoustic Test Rig Free-Jet Wind Tunnel

Research Objectives

- Supports acoustic research on nozzle and engine components

Description

- 53-in.-diameter free-jet acoustic wind tunnel

- Used to test a variety of aircraft technologies at simulated take-off and landing flight conditions up to Mach 0.30

Nozzle Acoustic Test Rig High-Flow Jet Exit Rig

- Single-flow and dual-flow configurations to simulate the engine core and fan flows of turbofan nozzle concepts

- Single-flow:

- Simulate nozzle exhaust conditions up to 1,425°F with a nozzle pressure ratio of 4.5

- Dual-Flow:

- Simulate core exhaust temperatures up to 1,280°F

- Fan/bypass temperatures up to 300°F

- Combined airflows up to 30+ lbm/s

- All air flows and temperatures independently controlled to allow large range of core/fan pressure and temperature ratios

- Optional independent third-stream airflow available

- Single-flow:

Advanced Diagnostic Testing Capabilities

- Temperature-pressure traversing plume survey

- PIV

- Laser Doppler velocimetry (LDV)

- Phased-array acoustic source identification

- Schlieren/Shadowgraphy

Model Data and Control System

- Pressure Systems

Netscanner is an off-the-shelf electronically scanned pressure system. The system consists of numerous 16 port, rack mounted modules (up to 640 ports). For the NATR, the following ranges are typically provided:- ±15 psid barometric reference

- ±30 psid barometric reference

- ±100 psid barometric reference

- +500 psid barometric reference

- Data System—Escort

Escort, the steady-state data acquisition system, uses a DEC Alpha microprocessor to provide:- An X Window-based system

- Real-time online acquisition of analog signals.

- Conversion of raw 10 Hz filtered digitized Neff data to engineering units

- Computed performance calculations, which can be displayed in a variety of graphical formats

- Limit checking on all selected changes

- 1 s update rate

- High-speed Dynamic Data Acquisition

- 32 channels currently available

- Portable Digital Temperature Scanner (DTS) System

- Allows up to 310 additional thermocouple channels to compliment standard facility channels

- Supports multiple thermocouple types

- Acoustic Capability

The NATR sits inside a geodesic dome specifically designed to allow for far-field (≈50ft) acoustic measurements of nozzle generated noise. The primary microphone array used for far-field data is located overhead and consists of 24 microphones positioned in an arc from 40° to 165°.- Additional microphone data channels are available to accommodate use of custom mic arrays to meet test specific research objectives as requested by customer.

- OptiNav Array 48 (48-channel): microphone phased-array system

Small Hot Jet Acoustic Rig

Research Objectives

- Supports jet noise fundamental research

Description

- All-in-one-platform that economically evaluates thrusts performance, acoustic performance, and plume turbulence characteristics of new nozzle concepts

Capabilities

- Test nozzle concepts with diameters up to 3 in.

- Simulated nozzle exhaust temperatures up to 1,300°F with a nozzle pressure ratio of 8.0

- Single flow configurations up to 6 lb/s

- Nozzle thrusts up to 100 lbs for cold flow test conditions

Advanced Diagnostic Testing Capabilities:

- PIV

- Shadowgraphy

- Schlieren

- Traversing plume-survey

DGEN Aero-propulsion Research Turbofan

Research Objectives

- Engine features and controls provide many advantages for versatile educational applications and for innovative and cost-efficient research projects. The small-scale nature of the engine provides a means for hardware testing of a turbofan engine at a modest cost.

Description

- The DART test rig is mobile, compact, lightweight and easilycontrolled by FADEC (Full-Authority Digital Engine Control).

- The DGEN engine is designed with inherent robustness, easy integration and maintainability, low fuel consumption and low noise level.

DGEN 380 Engine

- A small, separate flow, geared turbofan capable of producing 570 lb of thrust.

- The high-bypass-ratio, two-spool unmixed-flow turbofan architecture is representative of modern commercial engines.

- The DGEN 380 engine contains five primary turbo-machinery components. The high-pressure turbine (HPT) connects to the high-pressure compressor (HPC) via the high-speed shaft (HS). The low-pressure turbine (LPT) is connected to the low-speed shaft (LS) and drives the fan via the speed reducer gear box.

- The DGEN 380 has a bypass ratio of 7.6 and features a geared turbofan with a 3.32 ratio that links the low pressure spool to the fan spool.

- It uses a 14-in. diameter fan that has tip speeds that are subsonic.

DART TRUCK

- Mobile control unit houses all controls, video monitoring, data acquisition systems, and FADEC controls for the DART engine

- Houses qualified engine operators and research personnel during testing

- WESTT BR control bench integrated into the control bay of the truck

WESTT BR Control Bench

- Acts as the engine control unit by utilizing a Full-Authority digital Engine Control (FADEC).

- Allows for all pressure, temperature and mass flow rate monitoring at all engine component locations.

Measurement Capabilities

- Compact acoustic arena; 15-element inlet and exhaust microphone arrays positioned in 10-ft diameter arcs.

- AAPL facility 24-element overhead array used for far-field data when in far-field location.

Contact

Aero-Acoustic Propulsion Laboratory

Facility Manager: Jonathan Kubiak

216-433-8347

Jonathan.M.Kubiak@nasa.gov

Test Facility Management Branch

Branch Chief: Michael S. McVetta

216-433-2832

michael.s.mcvetta@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.