Safety Measures

Overview

Failure is a key element of experimentation of any sort, and the testing of rocket engines, particularly those using high-energy propellants, poses a number of hazards to both people and property.

Engine failures or the buildup of combustible gases in confined areas can cause explosions. The toxicity and corrosiveness of some propellants can result in health problems or damage equipment. In addition, engine testing frequently produces harmful noise levels.

The Glenn Research Center has dealt with these issues at the Rocket Laboratory and many of its other facilities since its inception. The Rocket Lab, particularly in the 1950s, posed some unique challenges. A combination of physical protections, safety reviews, and coordination were employed to mitigate these hazards.

Documents

- Rocket Lab Warning Sign article (1956)

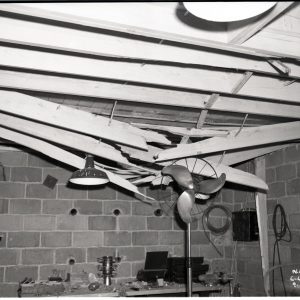

- Cell 22 Explosion Investigation (1957)

- Reorganization of Safety Committee (1960)

- Rocket Lab Safety Manual (1959)

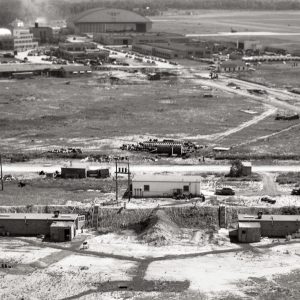

Physical Protection

The Rocket Lab was built at the far edge of the campus in the mid-1940s to separate it from the center’s other buildings. A river valley and wooded area segregated from the private property behind it. Dirt mounds were used to shield the different Rocket Lab buildings from one another. Additional protective mounds were constructed around the complex in 1949 to further block debris and damaging pressure waves. A concrete blast wall was erected next to Cell 14 by 1955. In the early 1970s, some of the walls in the rear portion of the facility were encased in metal to reduce their footprint.

By the mid-1950s, however, the center filled the empty areas of the campus with additional buildings and facilities. This coincided with the Rocket Lab’s testing of larger engines and higher energy propellants that were causing an increasing number of fires, explosions, and releases of toxic pollutants affecting both other buildings and the nearby community. In addition, some tests produced an acidic mist that damaged personal vehicles parked in the vicinity. Therefore, additional measures safety were employed.

Test Days

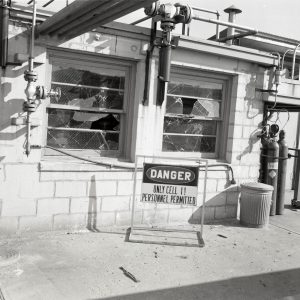

It was necessary to conduct most Rocket Lab testing in the evenings or over the weekend when the campus was empty. In 1956, a signpost was erected in front of the Rocket Lab Service Building with a red flag and posted scheduled test times to alert other employees of upcoming tests. Employees arriving at the Rocket Lab met with a security officer to exchange their NACA badge for a special badge allowing entrance to the area. Non-Rocket Lab employees could not enter the test cell areas without approval from the test engineer.

Each test cell had a yellow flashing light that was activated whenever pressurized propellants tanks were in use. Portable signs and chain barricades were set up on the roads and walkways around the test cell. Additional signage was employed when fluorine or other toxic propellants were in use. As the scheduled test time approached, security guards set up barricades to block access to the immediate Rocket Lab area and nearby parking lots. A horn sounded immediately prior to and during each engine firing. All facility personnel were expected to shelter in one of the buildings until it ceased.

An emergency crew, consisting of Rocket Lab personnel, was on duty during all testing to provide initial response to any accidents until the Lewis fire department arrived. The fire crew consulted with the emergency crew to determine the hazards before the latter entered the facility. Accident investigations were conducted after each incident.

Safety Reviews

The center formalized its safety activities in June 1950 with the establishment of an Executive Safety Board, which reported directly to the Director, and several technical safety committees. Two years later, a Safety Office was created to coordinate these activities. In 1960, each of the center’s facilities were placed under the jurisdiction of an Area Safety Committee.

These committees reviewed hazards and safety precautions prior to any testing within their assigned area. The committee members, colleagues with knowledge of the specific work being undertaken, met with the project engineers to discuss what steps were being taken to mitigate potential hazards to both personnel and the environment. Tests could not proceed without the committee’s approval.

In addition, the center had Hydrogen Safety and Special Fuels and Combustion committees to determine and enforce safety protocols for the storage, handling, transportation, and use of high-energy propellants. All modifications to Rocket Lab systems or test cells required approval from the Special Fuels and Combustion Safety Committee.

These combined efforts were largely successful in thwarting damage to surrounding areas. When additional rocket propellant testing facilities were needed in 1958, however, the center decided to build them at a remote facility 60 miles to the west where fewer precautions were necessary.