Coarsening in Solid Liquid Mixtures-3 (CSLM-3)

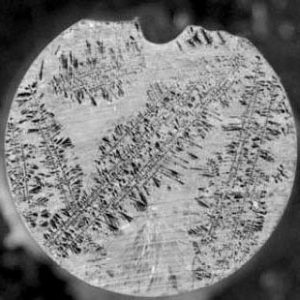

The CSLM-3 investigation expects to grow and examine metal dendrites (i.e., tree-like structures) that form during the solidification of all metals. Dendrites are also observed when water freezes and are called snowflakes. The spacing between the branches of the dendrite controls the mechanical properties of the solidified metals, such as engine blocks used in car engines. During the casting process the dendrites undergo a process called coarsening. During coarsening the dendrites change their shape, with a change in the spacing between the branches of the dendrites. Since the spacing alters the mechanical properties of the alloy, the coarsening of dendrites has a major effect on the properties of metal alloys. The objective of this experiment is to investigate this coarsening process without the complicating effects of convection of the liquid or sedimentation (e.g., gravity induce effects) of the dendrites.

In the predecessor CSLM-1 and 2 studies, spherical particles of the high volume liquid lead-tin fraction samples were observed during coarsening. The CSLM-1 and 2 experiments also used two-phase solid alloys as analogs that contained precipitates in a solid. The compositions of those alloys are very similar to those that are planned for use in the CSLM-3 experiments, the major difference being that the CSLM-3 alloy consists of solid dendrites rather than spherical particles. Research has shown that spherical particles coarsen in a very different fashion then dendrites.

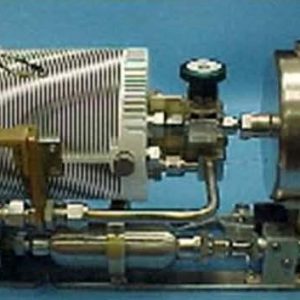

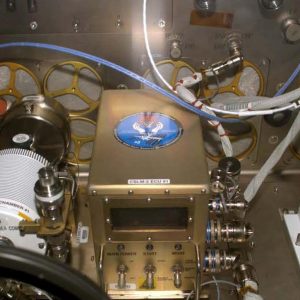

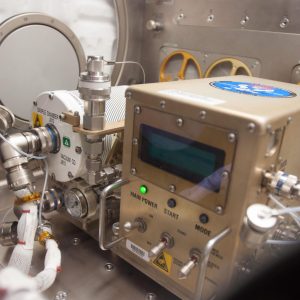

The CSLM-3 samples are a mixture consisting of Sn (tin)-rich particles in lead-tin liquid, a mixture that has a low sintering temperature and a high coarsening rate; making it perfect for studying the process of Oswald ripening. Sample runs are conducted inside the sealed MSG work volume using existing CSLM-2 hardware. Samples are processed inside a Sample Processing Unit (SPU), which has a cylindrical sample chamber. Each SPU contains 4 samples and crewmembers must load each SPU and initiate runs individually. Samples are heated to 185 degrees Celsius to enable dendrite growth. This temperature is maintained for various, predetermined intervals. Each isothermal heat soak time is unique for each SPU. After an SPU is processed, pressurized water is released into the chamber to quench the sample, cooling it down to lock in the structures. During a normal sequence the quench cycle is initiated automatically by the Electronic Control Unit (ECU). Quenching can be initiated manually if needed. Data captured by the ECU is transferred to the MSG laptop for storage and down loading to the ground-based researchers. The ECU provides power and controls all stages of the sample processing and experimental parameters and status are displayed on the ECU’s LCD display screen. The ECU also controls the temperature inside the SPU sample chamber and monitors and records the sample’s temperature. A baseplate is used to attach the SPU and ECU to the Microgravity Science Glovebox (MSG) work volume floor.

Previous Missions

The initial CSLM-2 investigations were conducted during ISS Increment 7. CSLM-2 high volume fraction samples were conducted during ISS Increment 16/17. CSLM-2R with low volume fraction samples were conducted during Increment 23/24.

Science Objectives

Science Objectives for Everyone

The Coarsening in Solid Liquid Mixtures-3 (CSLM-3) is a materials science investigation that studies the growth and solidification processes (i.e., coarsening) in lead-tin solid-liquid mixtures that contain a small amount (low volume fraction) of tin branch-like (i.e., dendritic) structures, some of which possess many arms. During sample heating, the growth at the tip of each dendrite continues over time, whereas side branches, behind the tip, develop during constant temperature (i.e., isothermal) conditions. By understanding how temperature and time control the growth of such dendrites, researchers hope to develop more efficient and economical means of producing higher quality products derived from the casting of molten metals.

Applications

Earth Applications

CSLM-3 examines the growth of metal dendrites (i.e., tree-like structures) that form during the solidification of all metals. This process is called coarsening and the growth of these dendritic structures within solid-liquid mixtures has major technological and production implications, since it occurs in virtually all casting processes. During the casting process, the coarsening of dendrites changes their shape and the spacing between branches of the dendrites, which alters the mechanical properties of the solidified metals and alloys, such as a car engine block. In the case where a dendritic structure forms quickly, a so-called “mushy zone”‘ is created. This mushy zone can exist, often for long periods of time, during which virtually every dendrite undergoes coarsening. The length of the dendrites in the mushy zone, and thus those present after complete solidification, are determined by the coarsening process and are intimately related to the mechanical properties of metal ingots. Through a better understanding and control of the formation of dendrites and anomalous structures this research leads to the production of more efficient methods and ultimately better products that are cast from molten metals and alloys.

Operations

Operational Requirements and Protocols

CSLM-3 is required to operate within the MSG. Crew support during setup, monitoring, processing of samples, data recording and stowing of investigation hardware is necessary. During both SPU pre and post processing, the temperature of each SPU is required to remain below 30 degrees Celsius.

- The crew unstows and sets up the CSLM-2 hardware (ECU, first SPU, baseplate, cables, and vacuum hose) in the MSG and runs any necessary vacuum cycles before testing each SPU which contains the lead-tin samples.

- Sample heating runs are initiated using a toggle switched on the ECU. Once started, the investigation runs autonomously.

- Individual SPU heat soak times range from 10 min, 1.6 hours, 5.5 hours, 13.5 hours, 27 hours, and 48 hours, followed by a quench cycle.

- When an individual sample run is completed, the crew downloads data from the ECU to the MSG laptop and switches samples by removing the SPU and replacing it with a new SPU.

- Once all runs have been completed, the hardware is removed from the MSG work volume and stowed.

- The processed SPU’s are stored on ISS until they can be returned to Earth. On Earth, the researchers analyze each sample for particle size distribution, particle morphology, matrix structure, and particle crystallographic orientation.

Related Documents

Data is currently unavailable.

Publications

Data is either unavailable, restricted, or under review.

Gallery

Contact Information

PI: Professor Peter W. Voorhees, Northwestern University

PS: Dr. Walter Duval, NASA GRC

PM: Robert Hawersaat, NASA GRC

Engineering Team: ZIN Technologies, Inc.