Coarsening in Solid Liquid Mixtures-2 (CSLM-2)

In an effort to reduce the total interfacial area per volume, two-phase mixtures undergo coarsening wherein large particles grow and small particles shrink. The process occurs via a diffusive mass transfer from small particles to large particles; thus, it is important for the particles to remain stationary in the matrix phase.

Materials containing a few large particles rather than many small particles can be structurally weaker; thus, the coarsening process affects the properties of many materials; such as aluminum alloys. To study this process in a system that can be directly compared to theory, investigators employ a two-phase solid-liquid mixture. Unfortunately, on Earth, the solid Sn-particles sediment to the top of the sample. Such a non-uniform distribution of particles is not observed in solid alloys or assumed in theory. Performing the experiments in space will allow investigators to study the coarsening process in a manner that can be directly compared to theory and other two-phase alloys.

CSLM-2 samples are processed inside the Sample Processing Unit (SPU), which has a large cylindrical sample chamber. After a sample is processed, pressurized water is pumped into the chamber to quench the sample, cooling it for removal. This system can quench the sample from 185°C (the temperature required to form the solid-liquid mixture and initiate coarsening in tin-lead (Sn-Pb) samples) to 120°C in only 6 seconds.

The Electronics Control Unit (ECU) provides power and the software that controls all stages of processing. Parameters and status are displayed on the ECU’s LCD screen. The ECU controls the temperature inside the SPU sample chamber and monitors and records the sample’s temperature. The quenching stage can be initiated automatically or controlled manually by the crew. A base plate attaches the SPU and ECU to the Microgravity Science Glovebox (MSG) work volume floor.

Previous Missions

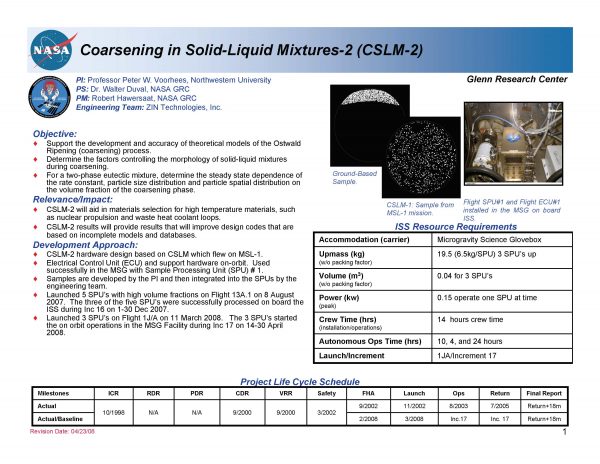

CSLM-1, a precursor to CSLM-2, was conducted on STS-83 and STS-94. CSLM-2 was conducted during ISS Expedition 7. CSLM-2 was conducted during ISS Increments 16 and 17. CSLM-2R with low volume fraction samples was conducted during Increments 23 and 24.

Science Objectives

Science Objectives for Everyone

Coarsening in Solid Liquid Mixtures-2 (CSLM-2) investigates the rates of coarsening of solid particles embedded in a liquid matrix. During this process, small particles shrink by losing atoms to larger particles, causing the larger particles to grow (coarsen) within a liquid lead/tin matrix. This study defines the mechanisms and rates of coarsening that govern similar processes that occur in materials such as turbine blades, dental amalgam fillings, aluminum alloys, etc.

Science Results for Everyone

Lumps in your hot chocolate are annoying; lumps in alloys can spell disaster. This experiment studied the rate at which particles of tin suspended in molten alloy increased in size. In this process, called coarsening, small particles shrink by losing atoms to larger particles, which then grow. Large particles can result in structural weakness, affecting materials such as dental fillings and aluminum alloys. Samples from an earlier low volume test were not returned to Earth in time for evaluation, but data was collected on equipment function. Samples from a later high volume run were successfully returned and are currently being analyzed. Other results show that particle size distributions in microgravity were very close to that predicted by theory. Analysis is ongoing.

Applications

Space Applications

In any mixture that contains particles of different sizes, the large particles tend to grow while the smaller particles shrink in a process called coarsening. Tiny oil droplets coalescing into a large blob are one illustration, but the process occurs in solids as well. Coarsening occurs on Earth during the processing of any metal alloy and thus the coarsening process affects products from dental fillings to turbine blades. Since the properties of an alloy are linked to the size of the particles within the solid, coarsening can be used to strengthen materials. This is the case with the majority of aluminum alloys used commercially today. Conversely, if the coarsening process proceeds too long the material can weaken. This occurs in jet turbine blades and is one of the reasons why turbine blades must be replaced after a certain number of hours of service. Thus developing accurate models of the coarsening process is central to creating a wide range of new materials from those used in automobiles to those used in space applications. The results of previous experiments performed on the Shuttle have done just that. These models have been incorporated into a computer code that is being used to design many new materials, including materials of importance to NASA’s spaceflight program. Solid-liquid systems are ideal systems to study this coarsening process. However, gravity can induce particle sedimentation and thus hamper the studies of coarsening in these mixtures on Earth. The microgravity environment of the Space Station allows scientists to study the process of coarsening with reduced interference from the sedimentation that occurs on Earth.

Earth Applications

On Earth, materials that contain pores created and trapped during solidification degrade properties and cause a distinct weakening in the overall structure of the cast product. Determining what causes these problems will lead to the development of improved manufacturing processes for materials.

Operations

Operational Requirements and Protocols

CSLM-2 will be conducted inside the sealed MSG work volume. The crew must load and initiate each run. Quenching can be initiated manually. Data captured by the ECU is transferred to the MSG laptop for storage and downloading to the ground-based researchers. The samples are a mixture consisting of Sn (tin)-rich particles in a Pb-Sn liquid, a mixture that has a low sintering temperature and a high coarsening rate; making it perfect for studying Ostwald ripening.

The crew will set up the CSLM-2 hardware and test it before running the first sample. The sample runs are initiated using toggles on the ECU. Once started, the experiments run autonomously. When the sample is completed, the crew will download data from the ECU to the MSG laptop and switch samples by removing the SPU sample chamber and replacing it with a new one. The processed sample chambers are stored until they can be returned to Earth by Shuttle. The hardware is removed from the MSG work volume and stowed after all the runs have been completed. On Earth, the researchers will study each sample for particle size distribution, particle morphology, matrix structure, and particle crystallographic orientation.

Related Documents

Data is currently unavailable.

Publications

Samples from CSLM-2 that were processed during Increment 7 were not able to be returned to Earth in time for evaluating the results. Although the data was lost, engineering data collected on equipment function can benefit subsequent experiments. The CSLM-2 high volume fraction samples from Increment 16 and 17 were successfully processed and returned for analysis during 2008. The CSLM-2R low volume fraction samples were successfully processed during Increment 23 and 24 and returned on Shuttle flight STS-133/Flight ULF-5 in March of 2011 and are currently under analysis at Northwestern University. Preliminary analysis of the low volume fraction samples indicates that the furnaces performed as planned. We are continuing to section the other samples to determine if this is case for all the volume fractions processed. Recent results show that the particle size distributions for a 30% volume fraction of coarsening phase is very close to that predicted by theory. The particle spatial distribution functions appear different, perhaps due to the nonspherical shape of the particles that are present at this high volume fraction. Analysis of both the low and high volume fraction samples is continuing.

Results Publications

- Physical Review Materials; Title: Coarsening of solid β-Sn particles in liquid Pb-Sn Alloys: Reinterpretation of experimental data in the framework of trans-interface-diffusion-controlled coarsening; Published: April 2021

- Cool T, Voorhees PW. The evolution of dendrites during coarsening: Fragmentation and morphology. Acta Materialia. 2017 April 1; 127359-367. DOI: 10.1016/j.actamat.2017.01.029. DOI: 10.1016/j.actamat.2017.01.029

- Duval WM, Hawersaat RW, Lorik T, Thompson J, Gulsoy EB, Voorhees PW. Coarsening in Solid-liquid Mixtures: Overview of Experiments on Shuttle and ISS. 2013 Materials Science and Technology Conference and Exhibition, Montreal, Quebec, Canada. 2013 Oct 27;

Related Publications

- Thomson JR, Casademunt J, Drolet F, Vinals J. Coarsening of solid-liquid mixtures in a random acceleration field. Physics of Fluids. 1997 9(5): 1336-1343. | Abstract

- Snyder V, Alkemper J, Voorhees PW. The development of spatial correlations during Ostwald ripening: a test of theory. Acta Materialia. 2000 482689. DOI: 10.1016/S1359-6454(00)00036-7. DOI: 10.1016/S1359-6454(00)00036-7

- Alkemper J, Snyder V, Akaiwa N, Voorhees PW. The Dynamics of Late-Stage Phase Separation: A Test of Theory. Physical Review Letters. 1999 822725. | Abstract

- Kammer D, Genau A, Voorhees PW, Duval WM, Hawersaat RW, Hickman JM, Lorik T, Hall DG, Frey CA. Coarsening In Solid-Liquid Mixtures: A Reflight. 46th Aerospace Sciences Meeting and Exhibit, Reno, NV. 2008 AIAA2008-813. | Abstract

- Kammer D, Genau A, Voorhees PW, Duval WM, Howersatt R, Hickman JM, Lorik T, Hall DG, Frey CA. Results from the International Space Station: Coarsening in Solid-Liquid Mixtures. 47th Aerospace Sciences Meeting and Exhibit, Orlando, FL. 2009 AIAA2009-0616. | Abstract

- Seyhan I, Ratke L, Bender W, Voorhees PW. Ostwald Ripening of Solid-Liquid Pb-Sn Dispersions. Metallurgical and Materials Transactions A. 1996 27(9): 2470 – 2478. | Abstract

- Rowenhurst DJ, Kuang JP, Thorton K, Voorhees PW. Three-dimensional analysis of particle coarsening in high volume fraction solid-liquid mixtures. Acta Materialia. 2006 54(8): 2027-2039. | Abstract

- Gulsoy EB, Wittman K, Thompson J, Voorhees PW. Coarsening in Solid-Liquid Mixtures: Effect of Microgravity Accelerations on Particle Sedimentation. 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL. 2011 Jan 4-7; AIAA 2011-1346-323

Gallery

Contact Information

PI: Professor Peter W. Voorhees, Northwestern University

PS: Dr. Walter Duval, NASA GRC

PM: Robert Hawersaat, NASA GRC

Engineering Team: ZIN Technologies, Inc.