BASS

Burning and Suppression of Solids (BASS)

The Burning and Suppression of Solids (BASS) investigation examines the burning and extinction characteristics of a wide variety of fuel samples in microgravity. The BASS experiment will guide strategies for extinguishing accidental fires in microgravity. BASS results contribute to the combustion computational models used in the design of fire detection and suppression systems in microgravity and on Earth

Research Summary

- Burning and Suppression of Solids (BASS) tests the hypothesis that materials in microgravity, with adequate ventilation, burn as well if not better than the same material in normal gravity with other conditions being identical (pressure, oxygen concentration, temperature, etc.).

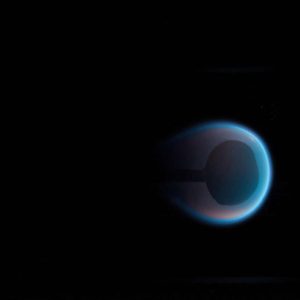

- There are important differences in the suppression of fires in space compared to on Earth. On Earth it is understood that the best results are generally obtained when the extinguisher “attacks” the base of the flame, which is both the stabilization point and the point where fresh air first enters the flame.

- For a fire burning in microgravity, the best point of application of suppressant may not be immediately apparent, especially for a partially obstructed flame or a wake-stabilized flame. Depending on the geometry of the flame and the characteristics of the extinguisher (distance from flame, dispersion angle) it is possible that the suppressant stream will be ineffective or might actually make the flame worse through the entrainment of oxygen. Using nitrogen as a flame suppressant in microgravity provides a direct link to current and planned extinguishment techniques.

Detailed Research Description

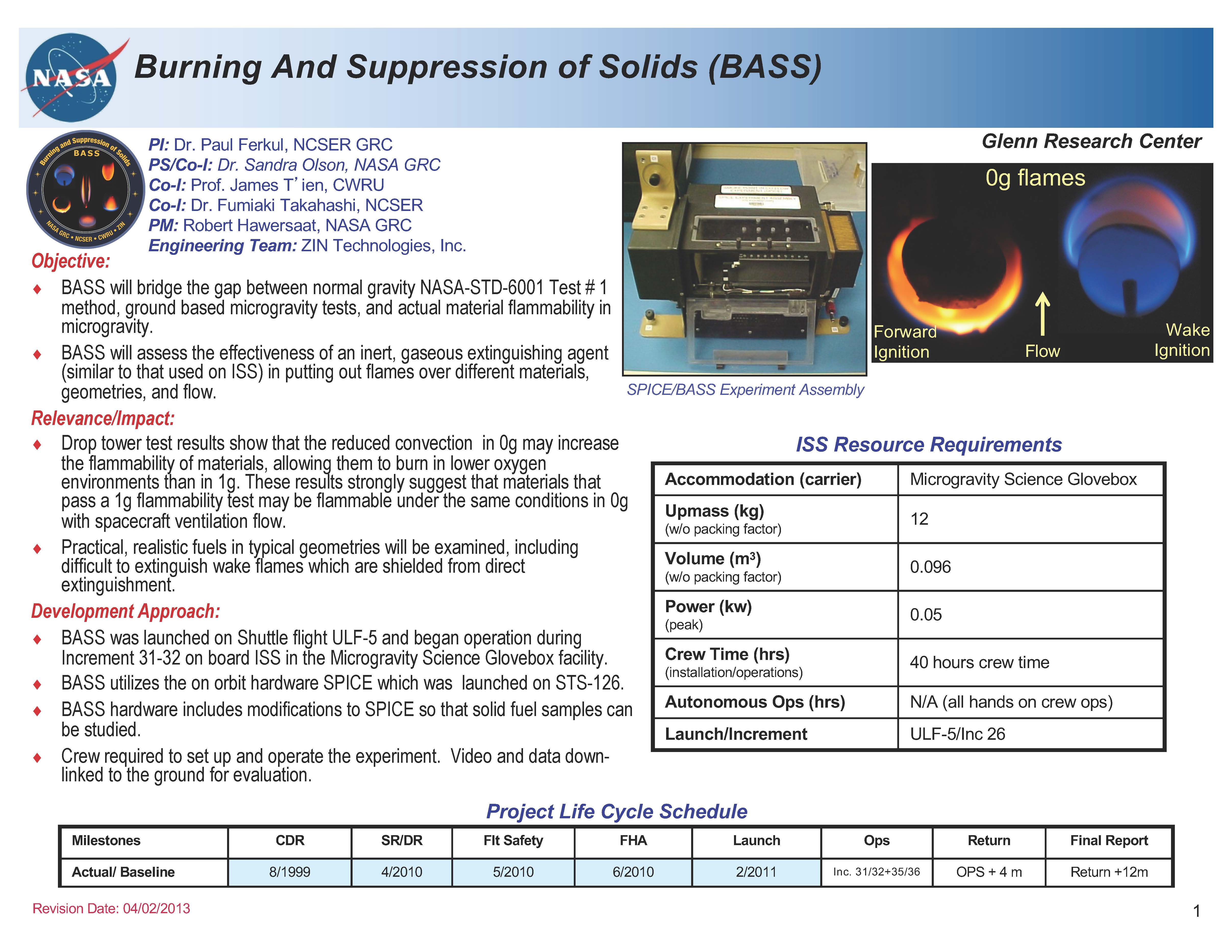

Burning and Suppression of Solids (BASS) utilizes slightly modified Smoke Point In Co-flow Experiment (SPICE) hardware within the Microgravity Science Glovebox (MSG) for observations of burning solid materials on board the ISS.

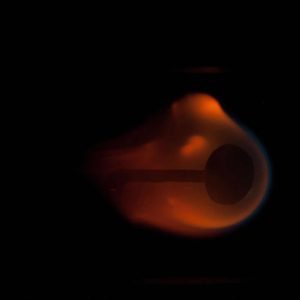

BASS consists of 41 fuel samples. There are three categories of samples: flat, solid spheres, and candles within tubes. Thin flat samples (12 cm long by 1 and 2 cm wide) yield concurrent-flow spread rate and limiting flame length. The cotton-fiberglass fabric blend Solid Inflammability Boundary at Low-Speeds (SIBAL) fuel is our principal thin material, and it was specially developed just for this purpose. Other thin materials are burned including Nomex and Ultem. Thick flat samples (5 cm long by 1 cm wide by 1 and 2 mm thick) of Polymethylmethacrylate (PMMA) and wax-saturated fiberglass fabric yield thickness effects on flame spread and extinguishment. Solid spheres of PMMA (1 and 2 cm in diameter) have the advantage of an axisymmetric geometry and permit multiple tests as the flame is extinguished and reignited. Ignition of either the front or back portion of the spheres is achieved. Finally, candles within a thin ceramic tube (6 mm in diameter by 25 mm long) are examined. Two types of wax are used, common paraffin and “Japan wax”, which has a very low soot point. For many of these tests, the nitrogen suppressant system is engaged at a gradually increasing level until extinction is reached.

The important experimental observations from BASS with respect to the burning process include flame shape and appearance as a function of flow speed, flame spread rate (how fast the flame develops), and flame dynamics (pulsations, oscillations, etc.). With respect to extinction, the critical observations and data are the time to extinction as a function of fuel geometry, the nitrogen flow rate, and the flame distance from the nozzle. The dynamics of the flame before extinction are also important for comparison to the modeling work.

The modeling effort includes:

- Modeling flame spread over flat samples: For flat samples, the steady spread characteristics can be examined using the three-dimensional model currently available. Alterations are the new tunnel and sample geometry and the upstream boundary condition. For the flame growing phase, a transient model is currently being developed.

- Suppression by nitrogen injection: This can also be modeled readily using the current model.

- Modeling burning and extinction of PMMA spheres: Similar problem on modeling two-dimensional circular PMMA cylinder in cross flow has been performed. Some changes are needed for the sphere and the duct flow.

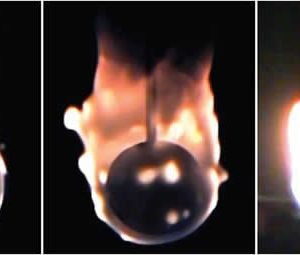

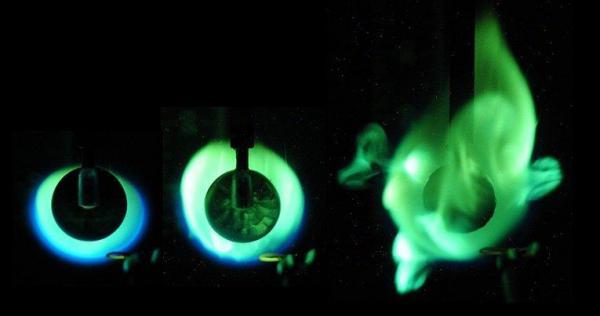

Zero-g facility test burning 2-cm-diameter PMMA sphere in 30 cm/s airflow. Left: 1 g; Middle: 0 g, 1 s after drop; right: 0 g, 4 s after application of nitrogen extinguishing agent. PMMA Sphere

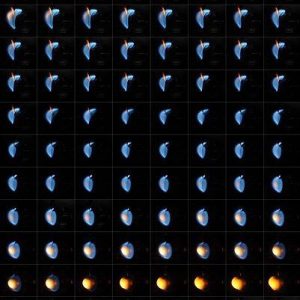

Drop tower results and modeling of a 2-cm-diameter PMMA sphere burning in 17% oxygen, 1 atm. pressure, at 2 cm/s forced convective flow. Experiment images are overlaid with computer simulations, which can capture the flame response as it transitions from 1-g to 0-g. Left-side contours show reaction rate (kgmol/m3/s); right side contours show temperature (K).

Brief Research Operations

- The crewmember unstows and assembles the BASS hardware on the base plate within the MSG working volume and connects electrical and data harnesses.

- Before each test point, the crew installs and positions fuel samples and igniters. Tunnel flow speed, nitrogen flow rate, and flame ignition are controlled.

- After ignition and some period of burning, the crew turns on the nitrogen suppressant at an increasing level until the flame goes out.

- The crew controls video and still camera functions. Some photos are downlinked for near-real time coordination with the investigator. The crewmember uninstalls experiment from the MSG and stows the hardware once BASS is completed.

Operational Requirements:

BASS is conducted inside the sealed MSG work volume. The crewmember is involved throughout the experiment to load fuel samples, initiate tests, ignite the fuel, adjust suppression, monitor and record data, exchange fuel samples, and replace the igniter. Forty-one test samples will be burned in a variety of flow conditions for a total of 89 test points.

Data is downlinked via video during or immediately after each flame test. Digital photos are downlinked after selected flame tests for ground confirmation before proceeding. BASS testing session must be conducted during periods when no major reboost or docking procedures are underway on the International Space Station (ISS).

Operational Protocols:

The crewmember installs the BASS hardware in the MSG work volume. The BASS hardware consists of a small flow duct with an igniter and a small nozzle along with exchangeable fuel samples. During BASS opeations a fan produces a co-flow of air through the duct. An anemometer is used to measure the actual flow rate. The crewmember adjusts the airflow from 5 to 50 cm/s. The flame is ignited and allowed to burn for about a minute. A nitrogen suppressant is then supplied via a mass flow controller, from 0 to 500 cc/min. A radiometer measures flame output. The crewmember conducts each test. They install the correct fuel assembly and set the air flow rate through the duct before igniting the flame. When the flame is ignited, the crewmember allows some time for the flame to stabilize then adjusts the flow of nitrogen suppressant through the nozzle until the flame goes out. After the test, the crewmember turns off the nitrogen flow and prepares for the next test. The science team on the ground monitors the video downlink to assist the crewmember in determining any peculiar flame behaviors and reviews the sensor data overlaid on the video image. Upon completion of the tests the crewmember stows the hardware and the stored images and data are returned to Earth for analysis.

Space Applications:

The current NASA spacecraft materials selection is based on a standard test method (NASA–STD–6001 Test 1) that segregates material based on 1-g behavior without consideration of low gravity effects. A critical element of this understanding is the radiative heat emission from the flame. These results are used in first order models and predictions of heat release in spacecraft fires and as a means to extend heat release data from tests like the NASA cone calorimeter test (NASA–STD–6001 Test 2) to a performance-based material selection process. Using nitrogen as a flame suppressant in microgravity provides a direct link to current and planned extinguishment techniques.

Earth Applications:

BASS results provide essential guidance to ground-based microgravity combustion research efforts. Detailed combustion models are validated using the simpler flow environment afforded by tests in microgravity. Once validated, they can be used to build more complex combustion models needed to capture the important details of flames burning in normal gravity. These models have wide applicability to the general understanding of many terrestrial combustion problems.

Related Publications

- Armstrong JB, Olson SL, T’ien JS. Transient Model and Experimental Validation of Low Stretch

Solid-‐Fuel Flame Extinction and Stabilization in Response to a Step Change in Gravity. Combustion and Flame. Vol. 147. pp. 262-‐277 (2006). - Ferkul PV, T’ien JS. A Model of Low-‐Speed Concurrent Flow Flame Spread over a Thin Fuel.

Combustion Science and Technology. Vol. 99. pp. 345-‐370 (1994). - Ferkul P, Kleinhenz J, Shih H-‐Y, Pettegrew R, Sacksteder K, T’ien J. Solid Combustion

Experiments Using a Continuous Fuel Dispenser for Use in Microgravity. Microgravity Science and Technology. Vol. XV/2 (2004). - Foutch DW. Size and Shape of Solid Fuel Diffusion Flames in Very Low Speed Flows. NASA CR-‐

179576 (1987). - Friedman R. Fire Safety in the Low-‐Gravity Spacecraft Environment. NASA TM-‐209285 (1999).

- Goldmeer JS. Extinguishment of a Diffusion Flame Over a PMMA Cylinder by Depressurization in

Reduced-‐Gravity. NASA CR-‐198550 (CWRU PhD Dissertation) (1996). - Hsu S-‐Y. Flame Spread and Extinction over Solids in Buoyant and Forced Concurrent Flows:

Model Computations and Comparisons with Experiments. Ph.D. Dissertation, CWRU (2009). - Ivanov AV, Balashov YV, Andreeva TV, Melikhov AS. Experimental Verification of Material

Flammability in Space. NASA CR-‐209405 (1999). - Jiang C-‐B. A Model of Flame Spread Over a Thin Solid in Concurrent Flow with Flame Radiation.

Ph.D. Dissertation. CWRU (1995). - Kimzey JH. Skylab Experiment M479 Zero Gravity Flammability. Skylab Results, Proceedings of

the Third Space Processing Symposium. Vol. 1. pp. 115-‐130 (1974) and NASA TMX-‐70252 (1974). - Olson SL, Ferkul PV, T’ien JS. Near-‐Limit Flame Spread Over a Thin Solid Fuel in Microgravity.

Twenty-‐Second Symposium (International) on Combustion. The Combustion Institute. pp. 1213-‐1222 (1998). - Olson SL, T’ien JS. Buoyant Low Stretch Diffusion Flames Beneath Cylindrical PMMA Samples.

Combustion and Flame. Vol. 121. pp. 439-‐452 (2000). - Shih H-‐Y, T’ien JS. A Three-‐Dimensional Model of Steady Flame Spread over a Thin Solid in Low-‐

Speed Concurrent Flows. Combustion Theory and Modeling. Vol. 7 (2003). - Takahashi F, Linteris G, Katta VR. Extinguishment Mechanisms of Co-‐flow Diffusion Flames in a

Cup-‐Burner Apparatus. Proceedings of The Combustion Institute. Vol. 31 (2007). - Takahashi F, Linteris G, Katta VR. Extinguishment of Methane Diffusion Flames by Carbon

Dioxide in Co-‐flow Air and Oxygen-‐Enriched Microgravity Environments. Combustion and Flame. Vol. 155, pp. 37-‐53 (2008). - Tseng Y-‐T. Ignition and Flame Growth in Concurrent Forced Flow Over Thick Solids. M.S. Thesis, CWRU (2007).

Gallery

Contact Information

PI: Dr. Paul Ferkul, NCSER GRC

PS/Co-I: Dr. Sandra Olson, NASA GRC

Co-I: Prof. James T’ien, CWRU

Co-I: Dr. Fumiaki Takahashi, NCSER

PM: Robert Hawersaat, NASA GRC

Engineering Team: ZIN Technologies, Inc.