BASS-M

Burning and Suppression of Solids-Milliken (BASS-M)

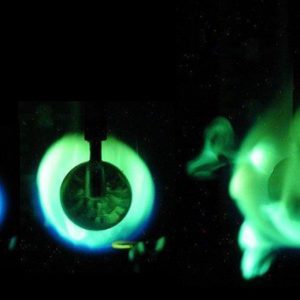

The Burning and Suppression of Solids-Milliken (BASS-M) investigation utilizes slightly modified Smoke Point In Co-flow Experiment (SPICE) hardware within the Microgravity Science Glovebox (MSG) for observations of burning solid materials on board the International Space Station (ISS).

The Burning and Suppression of Solids-Milliken (BASS-M) investigation utilizes slightly modified Smoke Point In Co-flow Experiment (SPICE) hardware within the Microgravity Science Glovebox (MSG) for observations of burning solid materials on board the International Space Station (ISS).

BASS-M consists of 44 textile samples with integrated igniter wires. There are four samples of each textile type, of which there are eleven. A set of control samples are included which provide untreated textile samples. The other ten sets of textile samples share a similar configuration. Each has a small piece untreated textile which is ignited by an integrated hot wire igniter. The flame from the untreated textile impinges on the treated textile which is immediately adjacent to the untreated sample.

The important experimental observations from BASS-M, with respect to the burning process, include flame shape and appearance as a function of flow speed, flame spread rate (how fast the flame develops), and flame dynamics (pulsations, oscillations, etc.). With respect to extinction, the critical observations and data to be collected are the time to extinction as a function of textile material and air flow. The dynamics of the flame before extinction are also important for comparison to the modeling work.

Research Overview

- The Burning and Suppression of Solids-Milliken (BASS-M) investigation tests the hypothesis that materials in microgravity, with adequate ventilation, burn as well, if not better than, the same material in normal gravity with other conditions being identical (pressure, oxygen concentration, temperature, etc.).

- BASS-M tests ten different treated textiles at various air flow rates found in forced convection in microgravity environments, or in a free fall environment. Each textile’s ability to self-extinguish is evaluated and compared against normal terrestrial behavior.

- NASA tests materials for flammability using an upward burning test, which is considered to be the worst-case geometry for flammability of the material on Earth. One objective of the BASS-M tests is to compare the microgravity results to the terrestrial upward burning used to screen the materials for safe use.

Space Applications

NASA selects materials for use in space based on ground tests of their flammability. But these tests do not consider the effects of microgravity, which changes how materials burn. This investigation conducts space-based burning and flame extinguishment tests on cotton textiles that have been treated with flame retardants. Results provide new knowledge of how low gravity affects a material’s flame-retardant behavior, improving procedures for testing new materials.

Earth Applications

Flame-retardant materials are designed to stop flames from spreading and consuming more material. This investigation provides new information on how low gravity affects a material’s flame retardant material behavior, which benefits materials science research on Earth.

Operational Requirements and Protocols

BASS-M is conducted inside the sealed MSG work volume. The crew member is involved throughout the experiment to load flame retardant textile samples, initiate tests, ignite the untreated textile sample, monitor and record data, exchange textile samples, and replace the memory card in the still camera. Forty-four test samples are burned in a variety of flow conditions for a total of 44 test points.

Data is downlinked via video during, or immediately after, each flame test. Digital photos are downlinked after selected flame tests for ground confirmation before proceeding. BASS-M testing session must be conducted during periods when no major re-boost or docking procedures are underway on the International Space Station.

The crew member installs the SPICE and BASS hardware in the MSG work volume. The SPICE and BASS hardware consists of a small flow duct with an igniter and a small nozzle, along with exchangeable textile samples. During BASS operations, a fan produces a co-flow of air through the duct. An anemometer is used to measure the actual flow rate. The crew member adjusts the airflow from 5 to 50 cm/s. The untreated textile is ignited and allowed to impinge on the treated textile until both extinguish, which takes about a minute. A radiometer measures flame output. The crew member conducts each test by installing the correct textile assembly, and setting the correct air flow rate through the duct before igniting the flame. After the test, the crew member prepares for the next test. The science team on the ground monitors the video downlink to assist the crew member in determining any peculiar flame behaviors, and reviews the sensor data overlaid on the video image. Upon completion of the tests, the crew member stows the hardware, and the stored images and data are returned to Earth for analysis.