Space Mechanisms Project

Developing novel mechanical assemblies and actuation methods for the extreme environments of aerospace.

Researching and developing materials, structures, and mechanisms technologies for propulsion, power, energy storage, and space and planetary environments. Engineering and testing expertise supporting mission success for advanced structural systems and mechanisms.

We develop materials technologies for high-performance, long-life, and lightweight aerospace systems.

Our focus is on materials for NASA aerospace systems subjected to extreme environmental conditions, such as those occurring in propulsion and power systems, planetary entry, planetary surface operations, and the space environment.

For more information, contact Joyce Dever.

Our fundamental research enables rapid discovery of novel alloys, ceramics, polymers, and composites designed for advanced processing methods, including additive manufacturing.

Our unique processing approaches, analysis capabilities, multiscale modeling methods, and machine learning tools contribute to new materials discovery.

For more information, contact Cheryl Bowman

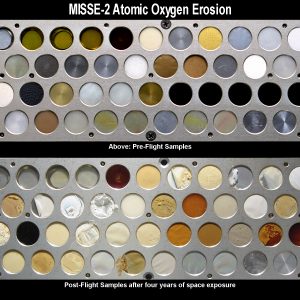

We’re enabling the reliable operation of components and structures subjected to extreme environments through development of robust materials systems.

Our in-depth understanding of environmental factors that impact the life and durability of materials is advancing research and technologies to mitigate environmental effects.

Research and experiments related to environmental durability in aerospace extreme environments.

For more information, contact R. Craig Robinson.

Our research is enabling new materials and components for highly efficient, lightweight electrical systems for aero and space power and energy storage.

For more information, contact Vadim Lvovich.

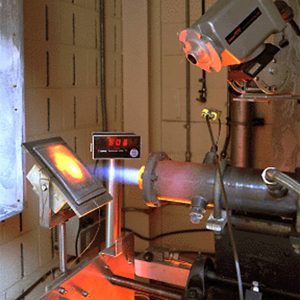

We develop and validate high fidelity models to predict performance and durability of materials and components under operational conditions.

Our unique facilities enable testing of materials and structures under a wide range of extreme conditions simulating aerospace application environments.

For more information, contact Nelson Morales.

We analyze and model material behavior and develop tools to predict failure and life for application conditions. We conduct structural analysis and modeling for static and dynamic conditions. We analyze and model performance of rotating machinery components in application environments.

For more information, contact Dr. John Ramsey.

We carry out analyses to examine and understand material and component failure under extreme operating conditions. Our testing capabilities provide a wide range of mechanical loading conditions as well as combined mechanical, thermal and environmental conditions to simulate specific applications. We test structures to examine effects of vibration, acoustics, impact, and shock. We perform testing for unique types of mechanical components including rover wheels, simulated lunar excavation tools, and electromechanical drive systems.

For more information, contact Trevor Jones.

We develop advanced mechanisms and actuation systems to provide robust, highly reliable, long life operation to support aeronautics and space missions under extreme environmental conditions.

Our key technologies include actuation components and rover wheel systems based on Shape Memory Alloys (SMA), seals for dusty environments and for high temperature applications, magnetic drive systems, novel mechanical drive systems and electromechanical component concepts.

Developing novel mechanical assemblies and actuation methods for the extreme environments of aerospace.

For more information, contact Irebert Delgado

Our work supports mechanical design and analysis of test hardware and ground systems. Our design efforts place a special emphasis on manufacturability and integration requirements. Our analysis work includes FEA structural modeling, fatigue / fracture mechanics and damage tolerance.

We provide static and dynamic analysis and testing of flight systems and structures for flight certification through implementation of the required engineering standards.

We play an important role in Materials and Processes (M and P), which is the assessment, qualification, and certification of materials.

For more information, contact Jack Dalzell.