Early Jet Engines

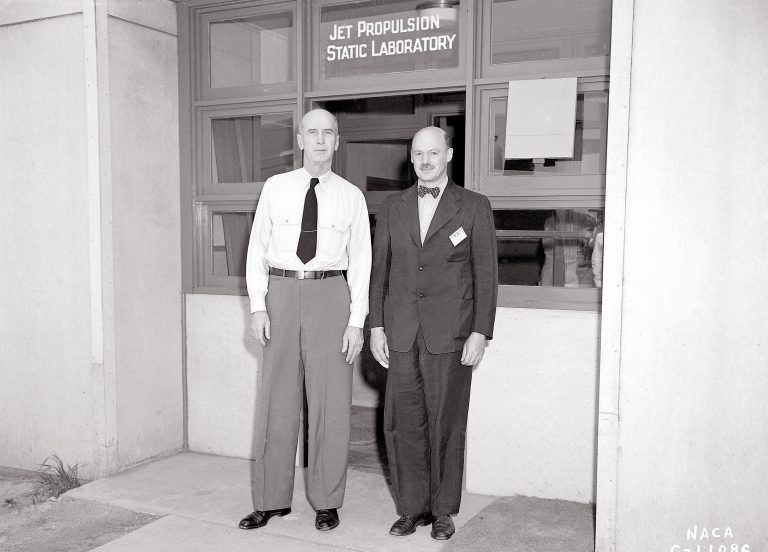

The Jet Propulsion Static Laboratory (JPSL) was hurriedly built in 1943 to secretly test early U.S. jet engines and afterburners during World War II.

Introduction

The Jet Propulsion Static Laboratory (JPSL) contributed to the center’s overall improvement of jet engine technology in the 1940s, particularly in increasing thrust. As industry needs evolved, the lab’s researchers began using the JPSL to develop better turbine blades and cooling systems in the 1950s. The 1960s Space Race introduced new areas of research, such as the handling and storage of cryogenic rocket fuels. By the late 1960s, however, the SPL returned to aircraft engine testing and materials analysis for engine components. Over the next three decades, researchers in the SPL used various burner, furnace, and laser rigs to make significant advances in thermal barrier coating (TBC) technology. These efforts continued up until the facility was closed in 2016.

Birth of the AERL

The National Advisory Committee for Aeronautics (NACA) was formed in 1915 to coordinate aeronautical research in the United States. Its laboratory in Cleveland, Ohio specialized in aircraft engines and offered many engine test facilities. In response to the emergence of the jet engine during World War II, the NACA hastily added the JPSL to the new laboratory. During the last two years of the war, NACA researchers used the JPSL to improve the performance of the nation’s earliest centrifugal turbojet engines.

The NACA, which was originally an advisory committee for industry and the military, began creating the NASA Langley Memorial Aeronautical Laboratory in 1917 so that it could hire its own aeronautical researchers to study aerodynamics and operational issues. In the ensuing years, Langley’s wind tunnels produced new airfoil and engine cowl designs that spurred the U.S. aviation industry.

During a period of increasing international anxiety in the mid-1930s, it became apparent that German aircraft could fly higher and faster than U.S. aircraft. The NACA decided to add two new laboratories, including one dedicated to propulsion. Construction of this new Aircraft Engine Research Laboratory (AERL) in Cleveland, Ohio commenced in early 1941. The AERL initially included six test facilities designed to address all aspects of the piston engines that powered all U.S. military aircraft. Most of the research staff transferred from Langley 1943.

Documents

- Model Research: National Advisory Committee for Aeronautics 1915-1958

- Place of NACA in U.S. Aviation (1943)

- Aircraft Engines for War from Engines and Innovation (1991)

Emergence of the Jet Engine

Unbeknownst to the NACA, however, both German and British engineers in the 1930s were designing a new more powerful aircraft engine—the turbojet. In May 1941, as construction of the AERL was just beginning, U.S. Air Command General Henry H. Arnold witnessed the first flight test of the British turbojet designed by Frank Whittle. The jet engine had the potential to dramatically improve the performance of military aircraft but required improvements before it would be viable. Arnold soon made arrangements to clandestinely transfer the design to the United States. By the end of the year, the United States had entered World War II.

The military turned the top secret drawings over to General Electric to quickly recreate the engine. Bell Aircraft was given the responsibility to design an aircraft to incorporate two of these new I-A engines. During flight tests in October 1942, however, the I-A’s performance was disappointing. In the ensuing month, General Electric redesigned the engine to be 10 to 15 percent more powerful. Flight tests of this I-16 (J31) engine during the summer of 1943 did not yield the desired improvements.

Documents

The Supercharger Building

General Arnold wanted the AERL to compare the I-A to the I-16 and make modifications to improve their performance. The lab’s massive Altitude Wind Tunnel (AWT) was still under construction at the time, so the military asked General Electric to rapidly design an engine test facility for the AERL. In July 1943 the military briefed some of the AERL’s Thermodynamics Section on the secret I-A engine and provided them with General Electric drawings for the JPSL. On July 10, 1943, the NACA issued a classified Research Authorization for “Investigation of Characteristics of Type I Engine” for the U.S. Army Air Force.

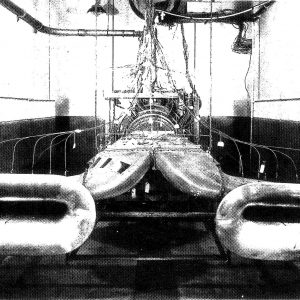

Construction of the secret facility, which as a subterfuge was originally referred to as “the Supercharger Building,” began immediately. The structure was located away from the other buildings along the fence line separating the lab from the Cleveland Municipal Airport. It has been reported that the facility was initially protected by barbed wire and an armed guard.

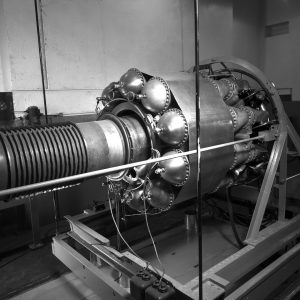

Upon completion of construction in mid-September 1943, AERL researchers immediately installed the two General Electric turbojet engines in the test cells. Over the next several months, they operated the engines over a range of speeds and applied modifications to improve performance. When the Altitude Wind Tunnel became operational in January 1944, an I-16-powered YP-59A aircraft was tested in simulated flight conditions. Although the researchers were never able to overcome the I-16’s inherent deficiencies, the effort led to the development of the first successful U.S. jet engine—General Electric’s I-40. The AERL used the I-16s as testbeds for a variety of research during World War II.

Documents

- Turbojet Revolution at Lewis Research Center (1984)

- AERL Wartime Research Authorizations (1943)

- General H.H. Arnold Speech to AERL Employees (1944)

- The Case for Jet Propulsion from Engineer in Charge (1986)

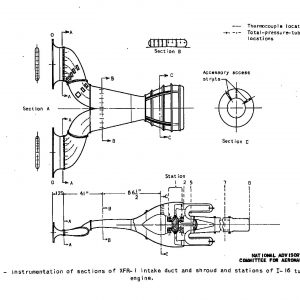

I-16 for the Ryan Fireball

Due to the unreliability of early jet engine designs, in 1943 the U.S. Navy asked Ryan Aircraft to create a fighter aircraft that utilized both the traditional piston engine and a turbojet. The result was the Ryan XFR-1 Fireball—the Navy’s first aircraft to include jet propulsion. A Wright R-1820 piston engine in the nose powered the aircraft during its patrol flights in the Pacific. The pilot would then switch to the I-16 engine in the tail to provide extra power when intercepting Japanese Kamikaze aircraft. Initial flight tests of the XFR-1 during the summer of 1944 revealed design issues. The Navy asked the AERL test the I-16 with a new intake duct, shroud and exhaust pipe.

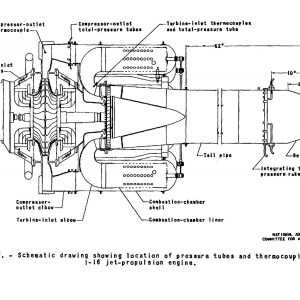

In September 1944, AERL researchers studied the XFR-1’s I-16 engine system in Cell 1 of the JPSL. The aircraft’s unique design required specially engineered curved intake ducts located in the wings. The researchers tested the engine’s intake ducts in several configurations and recorded attendant pressure losses. They also compared the performance of the XFR-1’s unique exhaust nozzle to that of the XP-59A. The former had a different contour and was twice as long as the latter.

The Navy ordered 600 of the aircraft and began incorporating them into its fleet in the spring of 1945. Preparations were still underway to send them into combat when the war ended in August 1945. Nonetheless, the Fireball was the first aircraft to land on a carrier using jet propulsion.

Documents

Fuels for Jet Engines

One of the AERL’s primary focuses during World War II was the analysis of fuels. The lab possessed the most advanced fuels research capabilities in the United States. Although most of this effort was geared toward identifying high-octane fuels for the military’s piston aircraft, it became apparent that very little was known about the effect of fuels on jet engines. In an effort to guide the way for future studies, the AERL initiated a study of different types of fuels on a General Electric I-16 engine in early 1945.

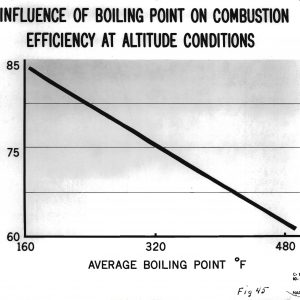

Researchers first analyzed the performance of an I-16 in Cell 1 of the JPSL with 14 different fuels, including gasoline, benzene, xylene, kerosene, diesel and several solvents. For each fuel, the engine was run for 20 minutes at increasing rates of speed. They found that neither the type of fuel nor its volatility affected the I-16’s combustion efficiency or thrust. Follow-up tests of a single I-16 combustion under simulated altitude conditions in another facility revealed that although increases in a fuel’s boiling point decreased combustion efficiency, the different fuels produced no significant differences in performance. NACA researchers continued to study fuels for turbojets, concentrating on their high-altitude performance, carbon deposits and availability. The combustion temperatures in turbojets are so hot that high-octane fuels were not required.

Documents

- Fuel Tests of I-16 Engine at Static Sea Level Conditions

- Fuels Research Talk at NACA Inspection (1947)