Design and Construction

The addition of the PSL No. 1 and 2 in 1952 provided the NACA with a state-of-the-art tool for studying the more powerful engines of the future.

Overview

In the late 1940s the National Advisory Committee for Aeronautics (NACA) realized it need a larger, more powerful facility to test the jet engines of the future in simulated altitude conditions. Design of the Propulsion Systems Laboratory (PSL) began in 1947, and construction followed in September 1949. The first test was run in October 1952.

Researchers used PSL during the 1950s to improve new turbojet and ramjet engines. Research shifted to chemical rocket engines during the early 1960s. By the late 1960s the center returned to aircraft propulsion and added two new test chambers to the facility. All four chambers supported the center’s aeropropulsion efforts during the 1970s. Reductions in funding led to the closure of PSL No. 1 and 2 in 1979. After sitting in mothballs for 25 years, NASA decided to demolish the original PSL test chambers in the 2000s.

Engine Testing at the AERL

Congress established the NACA in 1915 to coordinate aeronautical research in the United States. The NACA soon built a laboratory at Langley Field to conduct its own research. The NACA made many key aeronautical advancements during its first twenty years of its existence, but it had largely ignored aircraft engines. In the late 1930s, however, its leaders discovered the advanced state aviation in Germany. The NACA quickly decided to add two new laboratories, including one specifically designed to study engine systems. This new Aircraft Engine Research Laboratory (AERL) in Cleveland, Ohio became operational in 1942.

The first facility to come online at the AERL was the Engine Propeller Research Building, or Prop House. The Prop House contained four 24-foot-diameter test cells that could run 4000-horsepower piston engines in ambient conditions. The Altitude Wind Tunnel (AWT), which was completed in early 1944, was a much more complex and useful facility. It couple operate these engines in conditions that simulated altitudes up to 50,000 feet and at air speeds up to 500 miles per hour. The AWT was so successful that its schedule soon became backed up for months. The lab decided to quickly build two static engine test stands in the Engine Research Building. This Four Burner Area could also run full-size engines at simulated altitudes up to 50,000 feet. During the late 1940s and early 1950s, however, the jet engine was rapidly growing in power and size. It became clear that a more powerful test facility was needed at the lab (renamed the Lewis Flight Propulsion Laboratory in 1948).

Documents

- Model Research: The National Advisory Committee for Aeronautics, 1915 – 1958

- Engines & Innovation: Lewis Lab and American Propulsion Technology

- Bringing the Future Within Reach: Celebrating 75 Years of NASA Glenn

Designing the PSL

In 1947, the lab’s Research Facilities Panel began planning for a new facility that combined the static cell concept of the Four Burner Area with the massive infrastructure of the AWT. This was part of a comprehensive plan to improve the altitude testing capabilities across the lab by linking the exhaust, refrigeration, and combustion air systems from all the major test facilities. In this way, the systems at different facilities could complement the capabilities of one another. Congress allocated $10 million for the initial construction of the new facility, originally referred to as the Propulsion Sciences Laboratory. Within five months, veteran engineer Eugene Wasielewski converted the panel’s recommendations into design specifications. The Burns and Roe Company worked closely with the NACA engineers to create the master drawings from these specifications.

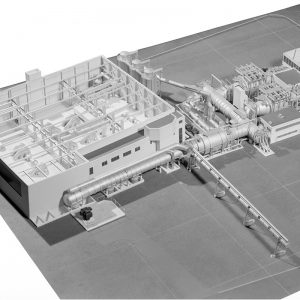

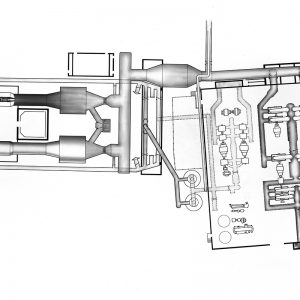

The overall concept of PSL was relatively simple, but the integration and performance of the massive systems was very complicated. The facility consisted of two test chambers, three exhaust gas coolers, an equipment building to house the exhausters and compressors, an access building, cooling tower, pump house, and an office building. It also included a compressed air system that supplied combustion air, an altitude exhaust gas system, research equipment installations, a cooling water system, electrical power system, as well as basic utilities, an intercommunication system, control rooms, roads, and a fire protection system.

Documents

- Preliminary Proposal for PSL (1948)

- Wasielewski Retirement article (1956)

- PSL Test Chamber Specifications (1948)

Original Construction

The NACA decided to construct the PSL in two phases.

The plan was to build the facility in two phases. The first provided the primary construction of the facility. The second phase, which began shortly after the facility became operational, significantly increased the PSL’s capacity. The Sam W. Emerson Company, which had built many of the lab’s buildings in the early 1940s, performed much of the basic construction work. The Elliott Company and the Ross Heater Company designed the massive compressors and coolers.

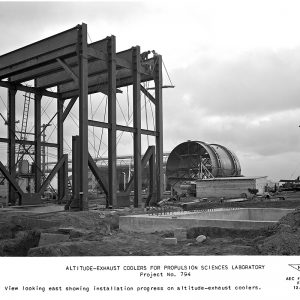

Construction began in late summer 1949 with the installation of an overhead exhaust pipe connecting PSL to the AWT and the Engine Research Building. Excavations for PSL began in September. In the spring of 1950, the crew erected the facility’s supports and installed the two large exhaust gas coolers. The large test section pieces arrived in early 1951 and work on the Access Building commenced. Construction of the Equipment Building began in early 1951, and the exhausters and compressors were added in the spring of 1952. The PSL was completed in September 1952, three years after construction began.

Documents

- PSL Construction articles (1948-50)

- New Altitude Test Facilities Aid Improvements of Turbojets (1952)

- PSL Construction Progress Reports (1949)

- PSL Construction Progress Reports (1950) pt 1

- PSL Construction Progress Reports (1950) pt 2