Design and Construction

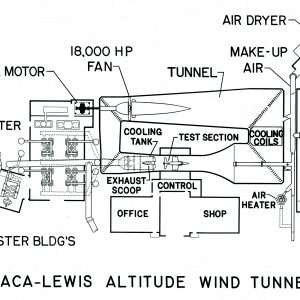

The NACA designed its unique Altitude Wind Tunnel (AWT) during World War II specifically to study the performance of aircraft engines in realistic simulated flight conditions.

Overview

As World War II intensified in January 1941, Chief National Advisory Committee for Aeronautics (NACA) Physicist Dr. Edward Warner stated, “The difference between freedom and subjugation is the difference between 400 miles per hour and 350 miles per hour; the difference between flying at 30,000 feet and 20,000 feet; the difference between twenty guns and four guns; the difference between a good engine and one that is not good.” German aircraft, at that time, outperformed those produced in the United States. This disparity stemmed from the United States’ lack of attention to engine technology.

The NACA created the Aircraft Engine Research Laboratory (AERL) and its Altitude Wind Tunnel (AWT) in the early 1940s to rectify that situation. The AWT was the most complete facility for testing full-scale engines prior to production. AERL Executive Engineer, Carlton Kemper, stated at the time, “[The] AERL is unique in having the only altitude wind tunnel in the world. We can expect that this one research tool will give answers to the military services that will more than offset the cost of the laboratory.”

Documents

- Girding for War chapter from Engines & Innovation (1991)

- Before Pearl Harbor chapter from Model Research (1985)

- AWT—A Tunnel for Engines from Wind Tunnels of NASA (1981)

Need for Altitude Testing

Congress established the NACA in 1915 to coordinate the nation’s aeronautical research. In 1918 the NACA created its own research laboratory at Langley Field, Virginia. The laboratory specialized in aerodynamics and largely left propulsion to industry. For instance, researchers used its Propeller Research Tunnel, built in 1927, to study drag caused by engine protuberances and propellers, but not the engine’s actual performance. Engine performance is affected by the cold temperatures and low air pressures found at higher altitudes. Engine designers need tools to study these issues. The National Bureau of Standards performed some altitude testing of its Liberty engine in 1917, but, in general, often dangerous flight tests were the only method of studying an aircraft engine in flight conditions.

Nonetheless, the NACA made a number of key technological contributions that helped produce a robust United States aviation industry during the inter-war period. While the nation invested its energy into producing large quantities of aircraft, the Europeans spent their limited funds on aeronautical and propulsion research. By the late 1930s European aircraft employed liquid-cooled engines and began the development of the jet engine. Their aircraft, though fewer in number than the U.S., could fly higher and faster.

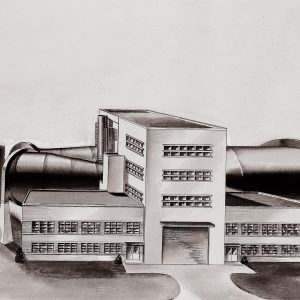

In the late 1930s, the NACA discovered the extent of the German aeronautical research program and initiated plans to create two new research laboratories. The Ames Aeronautical Laboratory would study high-speed flight, and the AERL in Cleveland, Ohio would concentrate on engines and propulsion technology. The AERL, now the NASA Glenn Research Center, included engine test stands, research aircraft, fuels and chemistry labs, and a massive wind tunnel designed to study full-scale aircraft engines in an altitude environment.

Documents

- AWT Comparison to Wright Tunnel (1941)

- Knudsen Letter on Need for AWT (1941)

- Bureau of Standards Engine Test for the NACA (1921)

- NACA No.1 Wind Tunnel Standardization Tests (1924)

A New Type of Tunnel

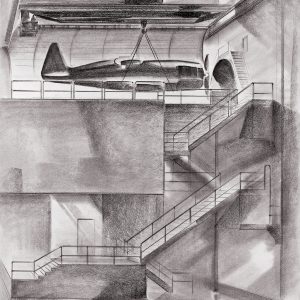

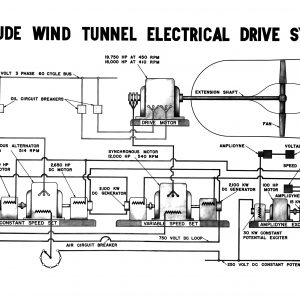

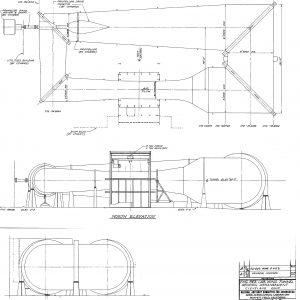

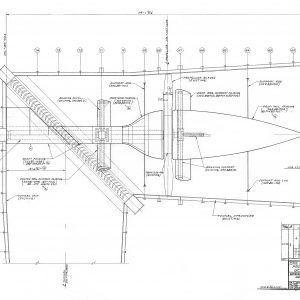

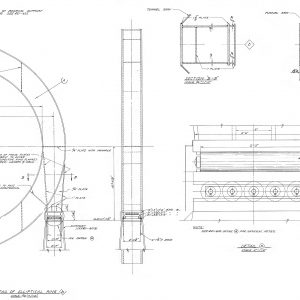

There were three distinct groups of engineers working on the AWT design between 1941 and 1943. At Langley, E. Raymond Sharp led a group of approximately 30 engineers and draftsmen that planned the structures and facilities for the AERL. The group included smaller teams working on specific facilities. Al Young and Larry Marcus led the team that designed the AWT’s fan, exhaust and make-up air systems, and support buildings.

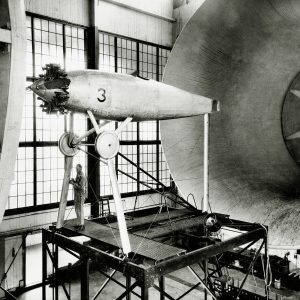

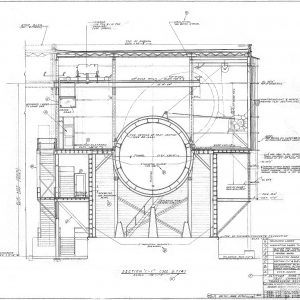

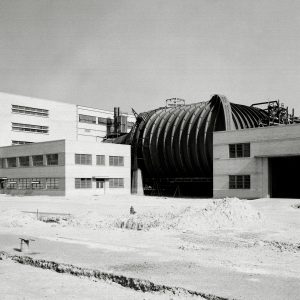

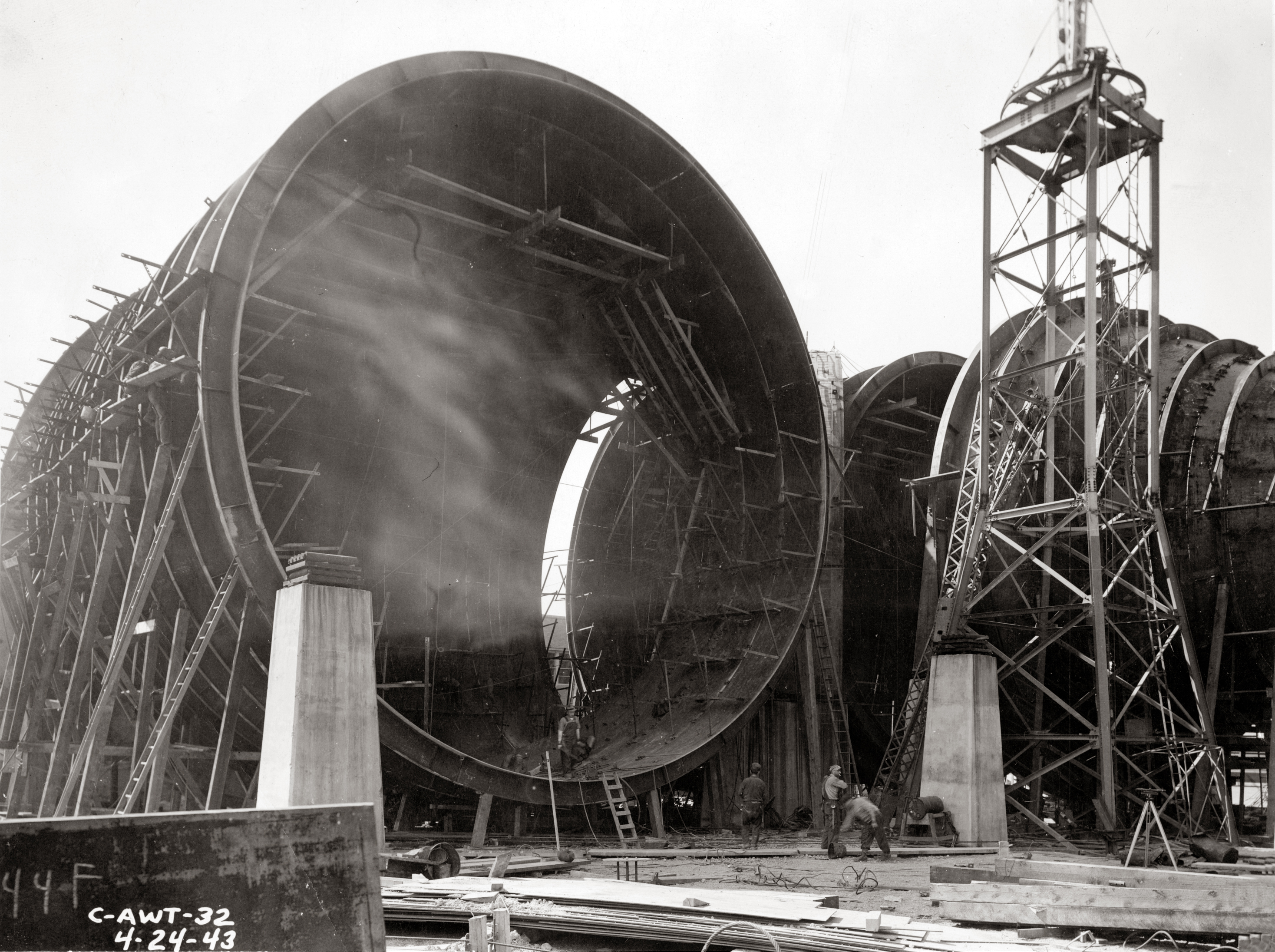

Carl Bioletti led a small team of engineers at the new Ames laboratory that designed the AWT’s distinctive shell and test section. The size of the 20-foot diameter test section was driven by the need to operate full-size engines and propellers. While small-scale models can be used to test airframes, engine research required full-size units. The need to create both the pressure and temperatures found at high altitudes made the design of the shell more difficult than the NACA’s existing wind tunnels. Ames’ engineers turned to Stephen Timoshenko, a leading structural analyst at Stanford University, to calculate the uneven stress loads for the AWT’s support rings and shell.

NACA engineers struggled to develop a method of reducing the AWT’s massive airflow to temperatures needed to simulate high altitudes. Willis Carrier, whose Carrier Corporation had pioneered the refrigeration industry, offered his company’s services to create an unprecedented cooling system. Carrier engineers arranged the tunnel’s cooling coils in a zigzag manner to increase the surface area. They also modified their high-compression compressors to accommodate the new Freon-12 refrigerant. The new system, which circulated over 20, 000 gallons of water per minute, was powerful enough to also cool the smaller Icing Research Tunnel. Carrier later considered the AWT project to be his company’s greatest achievement.

Documents

- AWT Refrigeration Request for Proposal (1942)

- Carrier in Wind Tunnel Air Condition history (1956)

- Refrigeration Plant Manual (1944)–extract

- Refrigeration Bldg Specs (1942)–extract

Construction Progress

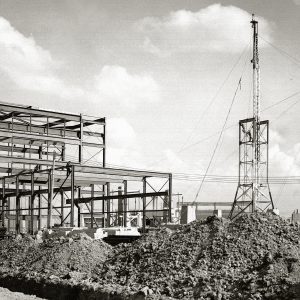

Construction of the AERL began in late January 1941, but the foundations for the AWT were not laid until the spring of 1942. By then the United States had entered the War, and the nation retooled to support the effort. This increased the need for the new wind tunnel, but also limited the supply of construction materials. The government began taking measures to accelerate the sluggish construction of the laboratory. The military provided special supplies, contractors were given new agreements and pressured to meet deadlines, and Congress approved additional funds.

By the fall of 1942, work on the AWT’s support structure and its Shop and Office, Refrigeration, and Exhauster buildings was underway. Progress on the tunnel and its infrastructure increased in 1943 as more and more of the lab’s other buildings were completed. The AWT’s support buildings were completed by September 1943, but work continued on the refrigeration and exhaust systems and the test chamber. After almost two years of construction, the AWT was finally completed in January 1944. Carrier and his team were onsite to verify that the cooling equipment performed correctly during its initial runs. Testing began almost immediately afterwards.

Documents

- Costs for Completion of AWT Construction (1943)

- AWT Construction Progress Reports (1941-43)

- Altitude Wind Tunnel articles (1944)