Electric Propulsion Research Building

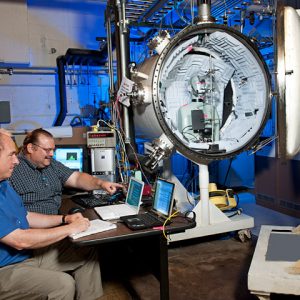

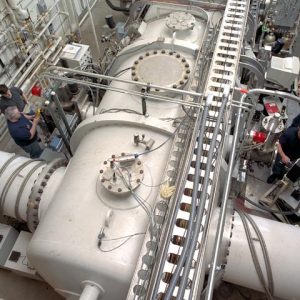

The Electric Propulsion Research Building (EPRB) has eight vacuum chambers and five bell jars that provide the required simulated space to conduct fundamental research in space power and electric propulsion.

Facility Overview

The Electric Propulsion Research Building (EPRB) supports research and development of spacecraft power, electric propulsion, and space environmental effects. Presently, EPRB is supporting research focused on ion thrusters, pulsed plasma thrusters, stirling engine converters, regenerative fuel cells, space plasma potentials, and atomic oxygen.

The cornerstone to EPRB’s research capabilities results from its suite of space simulation chambers. EPRB chambers range in size from bench top bell jars to 3-meters in diameter and are equipped with various pumping systems (cryopumps, diffusion pumps, oil-free pumping trains, and high-throughput roots-blowers) depending upon the specific requirements of a test program. In addition, EPRB has over 20,000 square feet of specialty labs, build-up area and machine shop area. EPRB works synergistically with other larger vacuum facilities located at GRC.

Research that is initiated in EPRB on a concept or component level leads to a system or higher fidelity tests in facilities such as VF-5 (very high pumping speed), VF-6 (unique in its electric propulsion features), or SPF (world’s largest vacuum chamber). This insures that these world-class facilities are effectively utilized and that research is done in the most cost-effective manner possible.

EPRB has eight vacuum chambers and five bell jars that provide the required simulated space to conduct fundamental research in space power and electric propulsion. These vacuum facilities are further enhanced to insure GRC continues to provide the technology development necessary for NASA to explore the solar system.

- VF-7 is surrounded by one foot thick concrete which makes it an excellent test bed for conducting research where safety may be a concern such as thrusters with hydrogen as a propellant or thrusters that produce plasmas through RF generation.

- VF-9 has the capability to produce atomic oxygen over a 1.5 meter by 2.1 meter area.

- VF-10 is equipped with an oil free pumping and LN2/GN2 cooled cold walls which facilitates qualification and acceptance testing of electrical components for space flight.

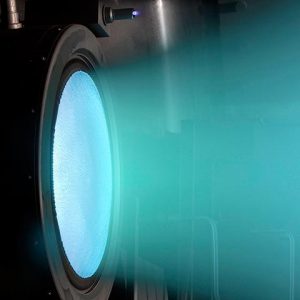

- VF-11 is a cryopumped facility with a pumping speed of 120,000 liters/sec for xenon. In addition to its ability to retain a high vacuum even when a thruster is propelling, VF-11 is equipped with diagnostic equipment that supports fundamental research on ion thrusters, hollow cathodes and plasma contactors.

- VF-16 is a cryopumped facility with a pumping speed of 250,000 liter/sec for xenon. VF-16 is equipped with an LN2-cooled target.

Quick Facts

The Electric Propulsion Research Building (EPRB) capability centers on its suite of vacuum chambers, which are configured to meet the unique requirements related to electric propulsion, spacecraft power, and space environmental effects. EPRB chambers range in size from bench top bell jars to 3-meters in diameter and are equipped with a variety of pumping systems (cryopumps, diffusion pumps, oil-free pumping trains, and high-throughput roots-blowers). In addition to the vacuum chambers, EPRB provides over 20,000 square feet of specialty labs, and assembly rooms.

| Name | Electric Propulsion Research Building |

|---|---|

| Vacuum Facilities |

|

| Total Area | 40,000 square feet |

Capabilities

General EPRB Capabilities

- Vacuum Facilities

- Eight vacuum chambers

- Multiple bell jars

- Production and Assembly Capabilities

- Hydroforming rig

- Hydroforms ion grids up to 50 cm in diameter

- Only facility capable of dishing grids larger than 25 cm

- Machine Shop

- Hydroforming rig

Vacuum Facility 1 (VF-1)

- Hollow Cathode Test bed

- Dimensions

- Overall 1.5m diameter by 4.5m long

- Vacuum System

- Pumping speed: 40,000 l/s air @10-6torr

- 3×10-7torr base (no load) pressure

- Automatic, unattended operation

Vacuum Facility 2 (VF-2)

- Electrodeless Thruster and Low Flow Propulsion Test Bed

- Low Flow Propellant

- Dimensions

- Overall 1.0m diameter by 1.8m long

- Vacuum System

- Pulsed Plasma Thruster Test Bed

- Pumping speed: 1950 l/s air @10-6torr

- 1×10-6torr base (no load) pressure

- Turbopump

- Dry-scroll roughing pump

Vacuum Facility 3 (VF-3)

- Dimensions

- Overall 1.5m diameter by 4.5m long

- Vacuum System

- Pulsed Plasma Thruster Test Bed

- Pumping speed: 80,000 l/s air @10-6torr

- 4×10-7torr base (no load) pressure

- (4) 35-inch diameter oil diffusion pumps

- -100° C cooled baffles

- Thrust Measurement stand

- Automatic, unattended operation

Vacuum Facility 7 (VF-7)

- High Power Electric Propulsion Vacuum Facility

- Dimensions

- 3m diameter by 5m long

- Vacuum System

- Pumping speed: 125,000 l/s @ 10-6torr

- 1×10-7torr base (no load) pressure

- (5) 35in diffusion pumps with baffles

- Surrounded by concrete, except for outside wall

- XE Gaseous Feed System

Vacuum Facility 9 (VF-9)

- Atomic Oxygen Environmental Testing

- Dimensions

- 0.6m wide x 1.5mhigh x 2.5m long

- Vacuum System

- Pumping speed: 15m3/min @1×10-2bar

- 1×10-3torr base (no load) pressure

- Roots Blower / stokes rough pump

- Atomic Oxygen Production

- RF produced

- 1.5m x 2.1m area

Vacuum Facility 10 (VF-10)

- Space Power Components

- Dimensions

- 1.0m diameter x 1.5m long vacuum chamber

- Vacuum System

- Pumping speed: Turbopump 1950 l/s helium @10-5torr

- 8×10-7torr base (no load) pressure

- Oil free pumping system

- Dry scroll roughing pump 500 l/s

- Thermal shroud

- 0.9m diameter by 1m long (35in x 41in deep)

- Controllable temperature range (-155°C to +150°C)

- LN2cooled if desired (-196°C)

- Automatic, unattended-operation controls

Vacuum Facility 11 (VF-11)

- Ion Propulsion Testbed

- Dimensions

- 2.2m-diameter x 8.25m long

- Vacuum System

- 1×10-7torr base (no load) pressure

- Pumping speed: 270,000 l/s @10-6torr

- Three 48-inch cryotubs and four 36-inch cryotubs

- Automatic, unattended-operation controls

- XE Gaseous Feed System

Vacuum Facility 14 (VF-14)

- Turbopump Belljar

- Dimensions

- .6m wide x .6m long x .9m high

- Vacuum System

- Pumping speed: 270,000 l/s air @ 10-6 torr

- 5×10-7torr base (no load) pressure

- Turbopump

Vacuum Facility 16 (VF-16)

- Electrostatic Thruster Test

- Dimensions

- Overall 2.75m-diameter- by 4.5m-long

- Vacuum System

- Pumping speed: 500,000 l/s air at 10-6torr

- 7×10-8torr base (no load) pressure

- Ten 48in Cryopump

Vacuum Facility 52 (VF-52)

- Dimensions

- 0.6m diameter by 0.6m

Vacuum Facility 54 (VF-54)

- Dimensions

- 0.6m diameter by 0.9m

Vacuum Facility 61 (VF-61)

- Hollow Cathode Life Test

- Dimensions

- Overall 0.3m diameter by 0.5m long

- Vacuum System

- Pumping speed: 30,000 l/s air @10-6torr

- 3.5×10-8torr base (no load) pressure

- 36-inch Cryopump

- Test Ports

- End Port: 0.33m diameter by 0.41m long

- Side Port: 0.33m diameter by 0.41m long

- Automatic, unattended operation

Vacuum Facility 65 (VF-65)

- Dimensions

- 0.4m diameter by 0.7m high belljar

Contact

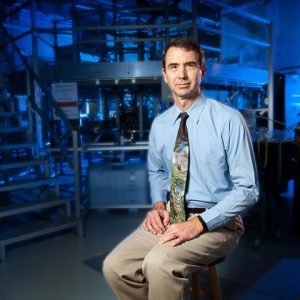

Electric Propulsion Research Building (EPRB)

Facility Manager: Ernest Williams

216-433-3554

ernest.t.williamsii@nasa.gov

Facility Manager: Lynn Arrington

216-977-7486

lynn.a.arrington@nasa.gov

Test Facility Management Branch

Branch Chief: Michael S. McVetta

216-433-2832

michael.s.mcvetta@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.