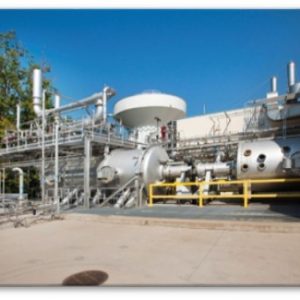

Chemical Propulsion Research Complex

The Chemical Propulsion Research Complex (CPRC) develops advanced chemical propulsion concepts and evaluates safer propellants for launch vehicles, spacecraft thrusters and advanced ignition systems for next generation launch vehicles. It has the capability to perform sea level and simulated altitude testing, as well as advanced plume diagnostics. Workhorse hardware is available to perform component level testing. The testing facilities that comprise the research complex are highly configurable and able to meet varying customer needs. These facilities include the Altitude Combustion Stand (ACS), and CPRC cells 31 and 32.

Facility Overview

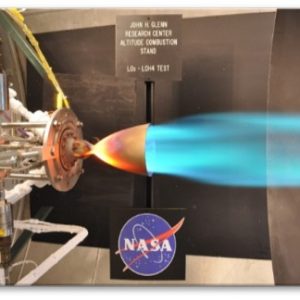

Altitude Combustion Stand

The ACS facility provides a system to test combustion components at a simulated altitude. The facility is equipped with an axial thrust stand, gaseous and cryogenic liquid propellant feed systems, water-cooled diffuser, data acquisition systems, video recording systems, facility control system, spray cooler and multi-stage vacuum ejector system. This facility has been used for testing since 2009. Propellant capabilities include GH2, GO2, LH2, LO2 and LCH4. The system can accommodate engines up to 2,000 pounds of thrust and combustion chamber pressure to 1,000 psia. Depending on the size, engines can be fired at sea level or into a test tank that is evacuated to simulated altitude up to 100,000 feet.

CPRC Cell 31/32

Cells 31 and 32 are both chemical propulsion test stands. Propellants include GH2, GO2 and LO2.Water can be used to cool the test article.

Quick Facts

| Name: | Altitude Combustion Stand (ACS) |

|---|---|

| Capabilities: |

|

| Simulated altitude |

|

| Available propellants |

|

| Name: | Chemical Propulsion Research Complex (CPRC) cells 31/32 |

|---|---|

| Propellants available: | GH2, GO2 and LO2 |

| Available cooling fluids: | Water |

Capabilities

Altitude Combustion Stand

| Propellant | Volume | Pressure, psi (MPa) | Flow rate, lbm/s (kg/s) | Inlet conditioning, R |

|---|---|---|---|---|

| LH2 | 200 gal (757.08 L) | 1,800 (12.41) | 1.5 (0.68) | N/A |

| GH2 | 140,000 scf (3,962.82 SCM) | 2,400 (16.55) | 2.6 (1.36) | N/A |

| LO2 (unconditioned) | 200 gal (757.08 L) | 1,800 (12.41) | 7 (3.18) | N/A |

| LO2 (conditioned) | 60 gal (227.13 L) | 525 (3.62) | 0.5 (0.23) | 145° to 243° ±5° |

| GO2 | 60,000 scf (1,698.35 SCM) | 2,400 (16.55) | 7 (3.18) | N/A |

| LCH4 (conditioned) | 60 gal (227.13 L) | 525 (3.62) | 0.16 (0.07) | 170° to 304 ° ±5° |

| Green Propellant AF-M315E | 12 gal (45 L) | 900 (6.21) | 0.11 (0.05) | 509° to 582° |

Facility Benefits

- Thrust measurements

- Cryogenic propellants

- Efficient multi-train vacuum ejectors

- Dedicated nitrogen gas system

- 400 channel data acquisition system

- Water cooling

- Reconfigurable, flexible systems

- In-house design and research staff available

Commercial Applications

- Igniter concepts

- Chamber and nozzle configurations

- Integrated engine systems

- Performance studies

- Pulse and steady-state firing

Chemical Propulsion Research Complex Cell 31/32

| Propellant | Volume | Maximum supply pressure, psi (MPa) | Flow rate, lbm/s (kg/s) |

|---|---|---|---|

| GH2 | 70,000 scf (1,981.41 SCM) | 2,400 (16.55) | 1.7 (0.75) |

| LO2 | 45 gal (170 L) | 1,500 (10.34) | 7.0 (3.15) |

| GO2 | 60,000 scf (1.698.35 SCM) | 2,400 (16.55) | 7.0 (3.15) |

| Water (cooling | 150 gal (567.81 L) | 1,500 (10.34) | 130 gal/min (492.10 L/min) |

Facility Benefits

- Thrust measurements

- Offers tailored test conditions in subscale combustion environments

- Provides test conditions to study ignition and combustion methods

- Cryogenic propellants

- 128-channel data acquisition system at 1,000 Hz

- Water cooling available for extended operation

- Capable of testing high-temperature thermal shock

Contact

Chemical Propulsion Research Complex

Facility Manager: Kyle Phillips

216-433-8871

kyle.g.phillips@nasa.gov

Test Facility Management Branch

Branch Chief: Michael S. McVetta

216-433-2832

michael.s.mcvetta@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.