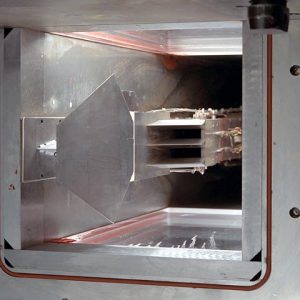

1×1 Supersonic Wind Tunnel

The 1- by 1-Foot Supersonic Wind Tunnel (1×1) specializes in conducting fundamental research in supersonic and hypersonic fluid mechanics, supersonic-vehicle-focused research and detailed benchmark quality experiments for computational fluid dynamics (CFD) code validation.

Facility Overview

The 1×1 is a facility located in the Engine Research Building (ERB) at NASA’s Glenn Research Center in Cleveland, Ohio. This facility is used to conduct fundamental research in supersonic and hypersonic fluid mechanics, supersonic-vehicle-focused research and detailed benchmark quality experiments for CFD code validation.

The tunnel can provide continuous operation at 10 discrete airspeeds from Mach 1.3 to 6.0 by using an appropriate fixed-area contoured nozzle block upstream of the test section.

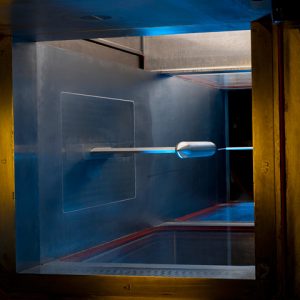

A number of specialized support systems are available to meet the research customer’s needs such as auxiliary bleed, model hydraulics, and probe actuation systems. Machine shop equipment is also available to accommodate model build-up and changes. The 1×1 uses several different types of experimental research tools that are invaluable to fundamental studies.

The facility has qualitative and quantitative flow visualization capabilities such as Schlieren imaging system, particle image velocimetry (PIV), a sheet-laser system, blue Zyglo (Magnaflux) and black lights, two-component laser Doppler velocimetry (LDV), and trace gas detection.

The equipment in the 1×1 is complemented by staff experienced in supersonic test hardware and experimentation. With its capabilities, expert staff, and efficiency, the 1×1 offers the supersonic research community an excellent low-cost tool for fundamental small-scale research.

Quick Facts

The 1×1 is used to conduct fundamental research in supersonic and hypersonic fluid mechanics. It is also used for supersonic-vehicle-focused research and detailed benchmark quality experiments for CFD code validation.

| Name: | 1- by 1-Foot Supersonic Wind Tunnel (1×1 ) |

|---|---|

| Mach no.: | 1.3 to 6.0 (10 discrete airspeeds) |

| Test section: | 1 foot high by 1 foot wide by 8 feet long |

- The 1×1 is a valuable tool to conduct fundamental research in supersonic and hypersonic fluid mechanics.

- It specializes in conducting fundamental research in supersonic-vehicle-focused research.

- The 1×1 offers the supersonic research community an excellent low-cost testing tool for small-scale research.

- It contains a number of specialized support systems, including auxiliary bleed, model hydraulics and probe actuation systems.

Capabilities

The 1×1 provides customers with a facility capable of conducting fundamental research in supersonic and hypersonic fluid mechanics.

Characteristics and Performance

- Mach number range: 1.3 to 6.0 (discrete number)

- Reynolds number: 0.4 – 16.5 × 106/ft

- Total temperature: 520 – 1100°R

- Dynamic pressure: 80 to 1750 lbf/ft2

- Maximum pressure: 165 psia

Flow Visualization

- Schlieren

- Sheet-laser system

- Blue Zyglo and blacklight

- PIV

Support Systems

- Model hydraulics

- Model air injection

- Auxiliary bleed

- Probe actuation systems

Research Instrumentation and Data Systems

- Pressure Systems

Electronically scanned pressure (ESP) is an off-the-shelf system. The system consists of numerous 32-port, rack-mounted modules from ±2.5 psid to +500 psid, located outside the test chamber. There are 576 configurable channels available. Each module has a check pressure to make sure that the module is performing correctly and can be calibrated in place using up to five highly accurate calibration pressures to maintain the overall system accuracy of ±0.05 percent of range. This calibration is performed every 2 hours. - Data System – Escort

- Escort is a steady state data acquisition system which provides:

- Real time on-line acquisition of analog and digital signals

- Conversion of raw data to engineering units

- Real-time monitoring of raw and calculated values in alphanumeric and/or graphical formats

- Limit checking available on any raw or calculated value

- 1-second update rate

- Various recording options are available from averaged to grouped (or cyclic)

- Data is usually provided in csv but can be modified to a specific customer format

- Escort can stand alone to meet all secure test requirements or can be connected to a central processing network. When connected to the network, the program can be accessed and maintained remotely which facilitates software application development, downloading of software, uploading and storage of facility files, post processing and transmitting of data to a data collector for archival storage. Escort provides the following:

- Accuracy for the analog to digital multiplexer is ±0.05 percent of range

- 240 channels of which 220 are available for the test article

- 48 temperatures from type E

- Escort is a steady state data acquisition system which provides:

- Dynamic Data System

The Dewetron data system provides multi-channel high speed digitized acquisition of rapidly changing cyclic or non-periodic impulse type events. The system consists of:- Real-time display and graphical capabilities

- Off-loading the data via file transfer protocol (FTP), in near real-time, to either a NASA computer or off-site computer for post-processing.

- 32, 24-bit analog-to-digital conversion (ADC) per channel

- A maximum rate of 200 thousand samples per second per channel.

Contact

1×1 Supersonic Wind Tunnel (1×1)

Facility Manager: Gwynn Severt

216-433-8310

Gwynn.A.Severt@nasa.gov

Test Facility Management Branch

Branch Chief: Michael S. McVetta

216-433-2832

michael.s.mcvetta@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

Did you test in one of our facilities? Let us know about your experience by participating in our customer facility evaluation survey.