Single-Aisle Turboelectric Aircraft with Aft Boundary Layer Propulsion (STARC-ABL)

In a new era of electric flight, NASA is exploring innovative Electrified Aircraft Propulsion (EAP) technologies to significantly reduce fuel burn and emission levels from single-aisle commercial aircraft transporting around 150 passengers. The Single-Aisle Turboelectric Aircraft with Aft Boundary Layer Propulsion (STARC-ABL) is a partially turboelectric aircraft concept developed to optimize vehicle performance through new aerodynamic designs and technologies.

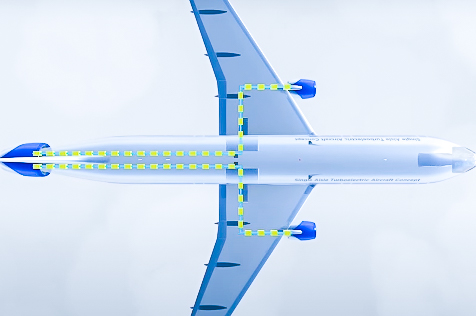

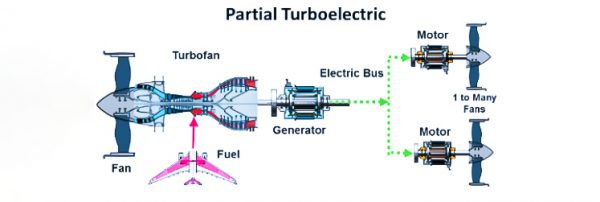

Maintaining a conventional turbine and airframe configuration, STARC-ABL employs a unique electric aft propulsor running on energy from two under-wing turbofan engines to help achieve maximum aerodynamic benefits during flight.

Operating with the same range, speed, and airport infrastructure of current regional jets, this aircraft concept could potentially reduce fuel burn by 7-12% and demonstrate the key opportunities in partially turboelectric propulsion systems for next-generation aircraft.

Aerodynamic Efficiency

Controlling the flow of air around an aircraft is a key first step in reducing drag, which slows the vehicle down and increases fuel burn. STARC-ABL features innovative Boundary Layer Ingestion (BLI) technology which helps manage slower-moving air near the surface of the aircraft, known as the boundary layer.

Integrated with the aircraft’s propulsion system, a BLI fan located on the tail of the vehicle helps ingest the layer of slower-moving, and often more turbulent, air. This air is then re-accelerated from the boundary layer at the surface of the aircraft to produce thrust.

Maximizing Performance

In order to achieve optimal performance, STARC-ABL relies on effectively incorporating its propulsion system with the flow of air around the airframe, known as propulsion-airframe integration (PAI). The turbofan engine under each wing of the aircraft is designed with generators to produce electricity and drive the rear motor.

This unique addition of a rear motor supplying additional thrust allows for smaller wing-mounted engines, which helps keep the overall aircraft weight down while minimizing drag and fuel burn. In addition to producing thrust, the turbofan engines are capable of generating megawatts of electricity which can be used to power the aircraft’s electrical systems, such as cabin cooling and onboard instruments.

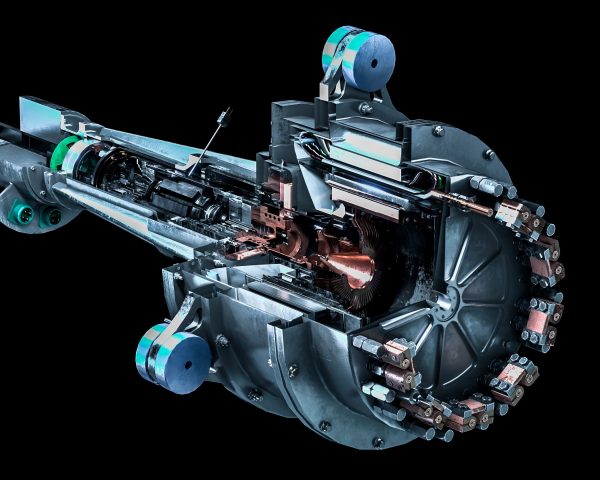

STARC-ABL requires an advanced 2-3 MW power system and features the High-Efficiency Megawatt Motor (HEMM) as a generator. HEMM is a 1.4 MW electric machine which offers three times less heat and weight loss that current aircraft motors and generators, and is key in enabling less drag and fuel consumption for STARC-ABL.

Demonstrating the possibilities

Slated for entry into the commercial fleet around 2035, STARC-ABL will play an integral role in demonstrating the capabilities of turboelectric systems and components for cleaner air travel.

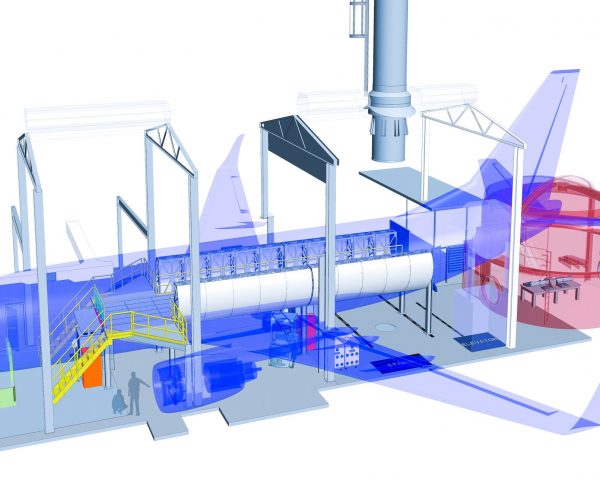

STARC-ABL will undergo extensive testing during the developmental phase of the concept aircraft at the NASA Electric Aircraft Testbed (NEAT) at NASA’s Glenn Research Center. This facility allows researchers to design, develop, and test full-scale electric aircraft power systems for large commercial airliners, and helps mature EAP technologies for future electrified aircraft.

The technologies demonstrated through this concept will help future airliners effectively transition away from traditional jet engine aircraft and into a more sustainable future for flight.